page 125

page 125

page 125

page 125

page 125

160B&C TM

800-00140

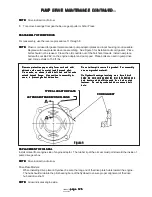

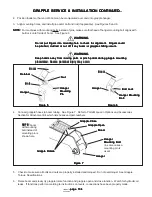

TYPICAL ADAPTOR PLATE

TYPICAL ADAPTOR PLATE

TYPICAL ADAPTOR PLATE

TYPICAL ADAPTOR PLATE

TYPICAL ADAPTOR PLATE

LET ENDS EXTEND BEYOND FLANGE

LET ENDS EXTEND BEYOND FLANGE

LET ENDS EXTEND BEYOND FLANGE

LET ENDS EXTEND BEYOND FLANGE

LET ENDS EXTEND BEYOND FLANGE

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: Drive in direction of arrow.

8. To remove bearings from gear hubs, use gear puller or Arbor Press.

REASSEMBLY OF PUMP DRIVE

REASSEMBLY OF PUMP DRIVE

REASSEMBLY OF PUMP DRIVE

REASSEMBLY OF PUMP DRIVE

REASSEMBLY OF PUMP DRIVE

For reassembly, use the reverse procedure of 1 through 8.

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: Plastic cord used for gasket material under pump adaptor plates and input housing is not reusable.

Replace with new material when reassembling. See Figure 3 for installation of cord gasket. Place

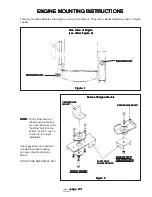

bolts should not be reused. Clean the old Locktite out of the bolt hole threads. Install new place

bolts with Locktite 262, on the engine adaptor and pump pad. Place bolts are used in pump drive

pad, torque studs to 150 ft. lbs..

Do not attempt to reuse this gasket. For assembly

Do not attempt to reuse this gasket. For assembly

Do not attempt to reuse this gasket. For assembly

Do not attempt to reuse this gasket. For assembly

Do not attempt to reuse this gasket. For assembly

use new gasket material.

use new gasket material.

use new gasket material.

use new gasket material.

use new gasket material.

On flywheel housings involving more than 4 bolt

On flywheel housings involving more than 4 bolt

On flywheel housings involving more than 4 bolt

On flywheel housings involving more than 4 bolt

On flywheel housings involving more than 4 bolt

holes, be sure cord gasket lap joint falls behind one

holes, be sure cord gasket lap joint falls behind one

holes, be sure cord gasket lap joint falls behind one

holes, be sure cord gasket lap joint falls behind one

holes, be sure cord gasket lap joint falls behind one

hole location which will be used for a bolt or stud

hole location which will be used for a bolt or stud

hole location which will be used for a bolt or stud

hole location which will be used for a bolt or stud

hole location which will be used for a bolt or stud

fastener. Do not lap ends behind an unused bolt

fastener. Do not lap ends behind an unused bolt

fastener. Do not lap ends behind an unused bolt

fastener. Do not lap ends behind an unused bolt

fastener. Do not lap ends behind an unused bolt

hole.

hole.

hole.

hole.

hole.

Remove protective paper strip from cord and with

Remove protective paper strip from cord and with

Remove protective paper strip from cord and with

Remove protective paper strip from cord and with

Remove protective paper strip from cord and with

adhesive side next to metal, install around pilot.

adhesive side next to metal, install around pilot.

adhesive side next to metal, install around pilot.

adhesive side next to metal, install around pilot.

adhesive side next to metal, install around pilot.

Cross ends, as shown, behind bolt hole and let ends

Cross ends, as shown, behind bolt hole and let ends

Cross ends, as shown, behind bolt hole and let ends

Cross ends, as shown, behind bolt hole and let ends

Cross ends, as shown, behind bolt hole and let ends

extend beyond flange. Use caution in assembly to

extend beyond flange. Use caution in assembly to

extend beyond flange. Use caution in assembly to

extend beyond flange. Use caution in assembly to

extend beyond flange. Use caution in assembly to

case, to prevent gasket dislocation.

case, to prevent gasket dislocation.

case, to prevent gasket dislocation.

case, to prevent gasket dislocation.

case, to prevent gasket dislocation.

CORD GASKET

CORD GASKET

CORD GASKET

CORD GASKET

CORD GASKET

Figure 3

Figure 3

Figure 3

Figure 3

Figure 3

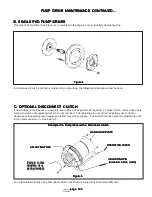

REPLACEMENT OF OIL SEAL

REPLACEMENT OF OIL SEAL

REPLACEMENT OF OIL SEAL

REPLACEMENT OF OIL SEAL

REPLACEMENT OF OIL SEAL

Install oil seal from engine side of engine adaptor. The rubber lip of the oil seal must point toward the inside of

pump drive gear box.

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: Drive in direction of arrow.

Drive Plate Models:

When installing drive plate on flywheel, be sure the long end of the drive plate hub is toward the engine.

The hub should slide into the pilot bearing bore of the flywheel to ensure proper alignment of the drive

hub and drive shaft.

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: Arrow indicates engine side.

PUMP DRIVE MAINTENANCE CONTINUED...

PUMP DRIVE MAINTENANCE CONTINUED...

PUMP DRIVE MAINTENANCE CONTINUED...

PUMP DRIVE MAINTENANCE CONTINUED...

PUMP DRIVE MAINTENANCE CONTINUED...