14 Industrial Ethernet Overview

14.1 Device Setup

14.1.1 Set IP Address

When shipped, the device is assigned a default IP address of 192.168.0.1, a default Subnet Mask of 255.255.255.0, and a

default Gateway of 0.0.0.0. To change these defaults, go to Main Menu > System > Communications > Ethernet I/O.

14.1.2 Set the Industrial Ethernet Protocol (Ethernet/IP

™

/Modbus/

PCCC/PROFINET

®

)

The Industrial Ethernet communication channel is disabled by default. To enable this channel, go to Main Menu > System >

Communications > Industrial Ethernet > Connection. Select the desired channel: Ethernet/IP, MODBUS, PCCC, or

PROFINET. Only one type of connection can be established at a time.

View information about an established connection from Main Menu > System > Communications > Industrial Ethernet >

Status. Click the desired connection to view details.

This device provides extensive logging for the communication that occurs over the Industrial Ethernet connection. View logs

from either Main Menu > System > Communications > Industrial Ethernet > View Logs or Main Menu > Logs >

Communication Logs > Industrial Ethernet.

14.1.3 Set Trigger Mode

Trigger the iVu BCR using the hardware trigger input line or an internally supplied software trigger, or by toggling a bit over

Industrial Ethernet. To only accept triggers generated through the Industrial Ethernet communication channel, go to Main

Menu > Imager > Trigger, and select Industrial Ethernet Only from the drop-down list.

14.2 Supported Functions

Control the iVu BCR over EtherNet/IP, PCCC, Modbus/TCP, or PROFINET using the input and output data the iVu BCR

makes available as a slave device for those protocols.

The following are some of the device operations that can be performed using input and output values:

• Product Change

• Teach Enable

• Trigger the iVu BCR

• Read output indicators (pass, fail, ready, error)

• Read counters (pass, fail, system error, missed trigger, frame count, iteration count)

• Read sensor results

14.2.1

iVu BCR

Input Values

The operation of the iVu BCR can be controlled through input bits and commands.

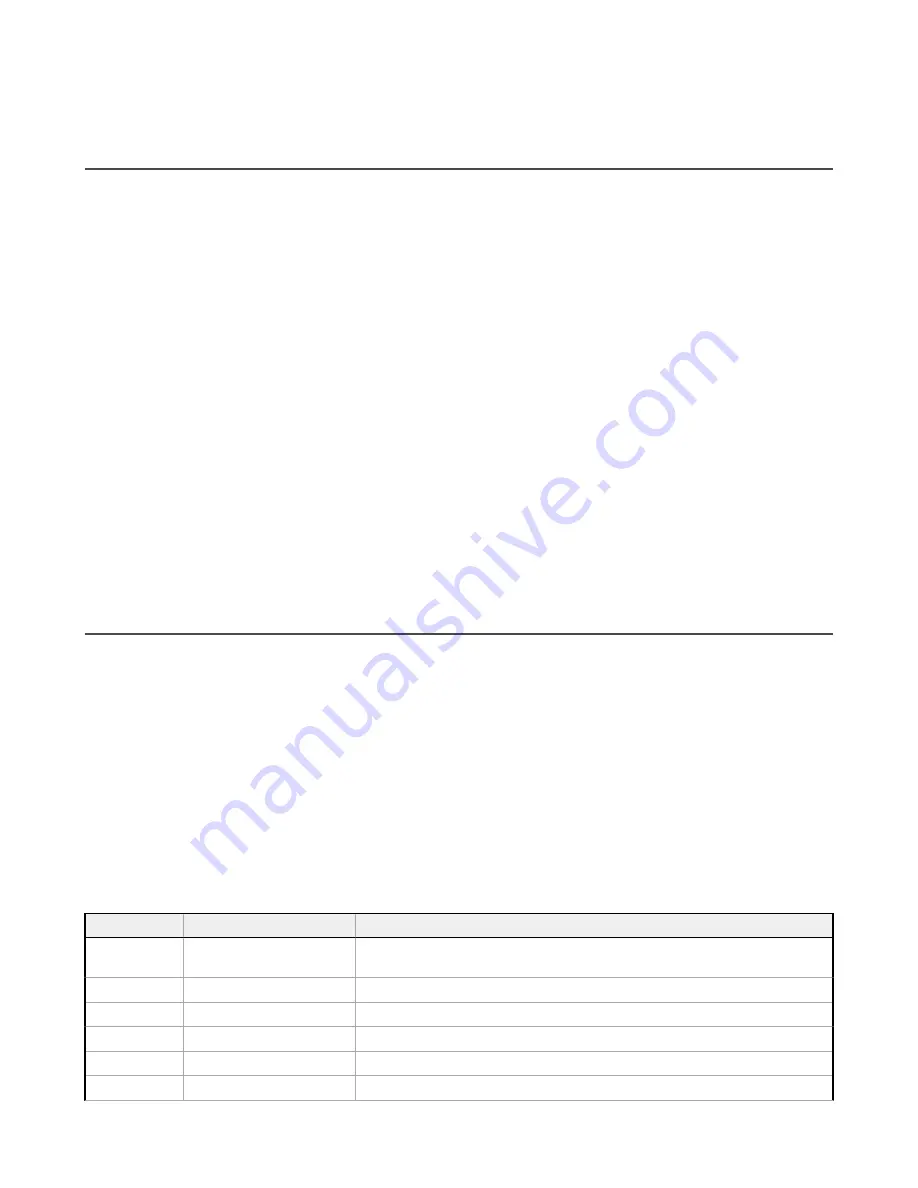

Register/Input Coil Bits

The following commands can only be executed using bits:

Input Coil Bit

Command

Description

0

Product Change

Execute a product change (inspection number specified in the "Product Change

Number" 32-bit integer register)

1

Teach Latch

Latch a teach flag. The Teach is executed on the next trigger

2

Trigger

Causes the iVu BCR to run the current inspection

3

Gated Trigger

Causes the iVu BCR to start looking for requested barcodes

5

Set BCR String

Sets the barcode compare string

6

Set BCR Mask

Sets masks for the barcode compare string

iVu Plus BCR Gen2 Series Sensor

www.bannerengineering.com - Tel: + 1 888 373 6767

99