H. Re-Machining Nozzle Seats

1. Remove the nozzle from the valve to be

remachined. If it cannot be removed from the

base, re-machine it inside the base.

2. Take the following steps to setup the lathe and

nozzle:

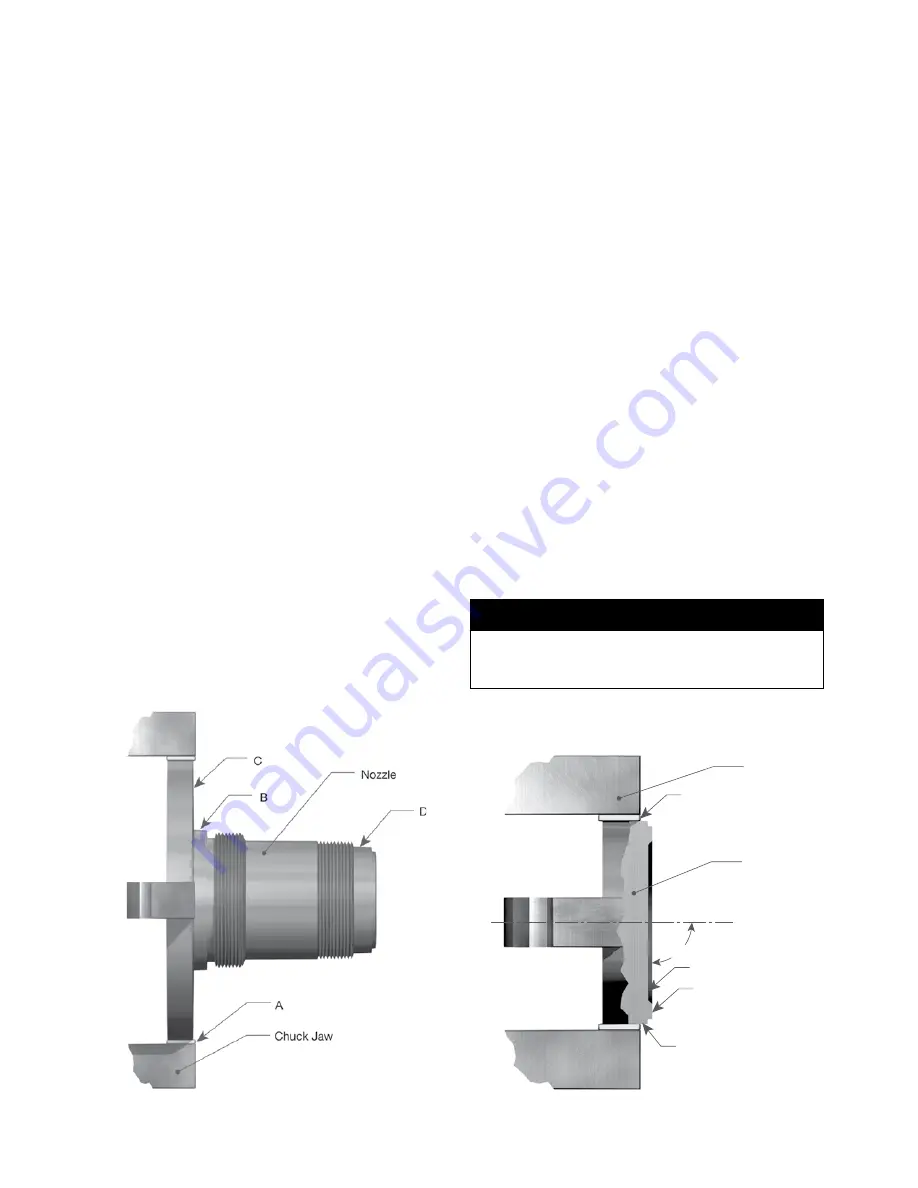

a. Grip the nozzle in a four-jaw independent chuck

(or collet, if appropriate), using a piece of soft

material such as copper or fiber between the

jaws and the nozzle as shown at A (Figure 32).

b. True up the nozzle so that the surfaces marked

B and C run true within .001” (0.03 mm) on

indicator (Figure 32).

3. Take the following steps to re-machine the

metal-to-metal nozzle (Figure 27a and Table 2):

a. Make light cuts across the surface L at 5º until

the damaged areas are removed. Turn to the

smoothest possible finish.

b. The nozzle is now ready for lapping.

c. When the minimum dimension H is reached,

discard the nozzle.

4. Take the following steps to re-machine the O-Ring

seat seal (Figure 27b and Table 2):

a. Make light cuts across surface A (45º) until

the damaged areas are removed. Turn to the

smoothest possible finish.

b. Re-machine radius R.

c. The nozzle is now ready for lapping.

d. When the minimum dimension H is reached,

discard the nozzle.

I. Re-Machining the Disc Seat

Take the following steps to machine the standard disc

seating surface (Figure 33):

1. Grip the disc in a four-jaw independent chuck (or

collet, if appropriate), using a piece of soft material

such as copper or fiber between the jaws and the

disc as shown at A.

2. True up the disc so that the surface marked B and C

run true within .001” (0.03 mm), TIR.

3. Make light cuts across the seating surface L until

damaged areas are removed. Turn to the smoothest

possible finish.

4. The disc is now ready for lapping.

5. Discard the disc if the minimum dimension N or T

(Figure 34, Table 5) is reached. Do not reestablish

surface C.

ATTENTION!

Do not remachine a Thermodisc or O-Ring Retainer.

Figure 32: Nozzle Positioned in a Jaw

C

90°

L

B

Disc

Chuck Jaw

A

Figure 33: Standard Disc Seating Surface

XIV. Maintenance Instructions (Contd.)

40 | BHGE

© 2018 Baker Hughes, a GE company. All Rights Reserved.