801683

125

Section 5 Service Procedures

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

• Motor not grounded! Disconnect electric power before servicing motor.

W485

WARNING

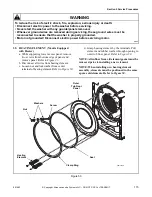

n. Disconnect ground wire from outer tub front

.

o. Remove nut, washers and screw holding clamp

ring to outer tub front panel. Refer to

.

p. Remove rubber seal from outer tub front panel

and discard seal.

IMPORTANT: Always replace seal with a new seal.

Spray or apply a mixture of diluted laundry

detergent to assist in installation of new seal. The

“puffy” side of seal should be installed to the inside.

For best results, tap clamp ring all around while

tightening screw and nut.

NOTE: Install clamp screw with threads and nut

facing downward. Refer to Figure 51. Install clamp

screw with threads and nut facing downward. Refer

to Figure 51. Install metal clamp ring by placing

clamp ring opening at approximately the 10 o’clock

position to ensure no interference is encountered

with side panel or the underside of the control

cabinet or cabinet top. Tighten screw and nut until

a spacing of one inch is achieved at the clamp ring

opening. Tap clamp ring all around while tightening

the screw and nut.

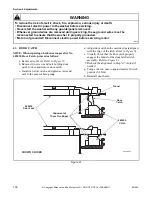

q. Run belt off pulley while slowly turning pulley.

.

r. Remove belt from motor shaft.

s. Remove cap screw (left hand thread),

lockwasher and flat washer holding pulley to

inner basket shaft. Refer to

NOTE: Cap screw can be accessed through hole in

rear panel by removing hole plug. Refer to

Figure 55.

t. Remove pulley from shaft.

IMPORTANT: When installing pulley, always use a

new cap screw to prevent screw from loosening

during operation. Use a thread tap to clean old

Loctite out of pulley screw receiving hole before

installing new screw. This ensures that inner basket

and pulley properly seat.

NOTE: When installing new cap screw, apply a

thread locking compound to screw threads and

torque new cap screw to 240 minimum to 260

maximum inch pounds (27.5 to 29.7 Nm).

u. After installing belt, adjust belt tension per

.

v. Carefully remove inner basket out through

front of washer.

w. Remove three screws holding bearing housing

arms to outer tub.

IMPORTANT: Prior to disassembly, note the

position of the pressure hose, hose clips and

mounting plate so parts can be reinstalled in the

same position. Refer to Figure 55.

x. While supporting bearing housing, remove

three inner screws holding bearing housing to

rear of outer tub. Refer to

Bearing Housing Installation –

NOTE: When installing the bearing housing, be

sure to route the pressure hose under the right arm

and attach hose and pressure hose clip to mounting

plate. Refer to Figure 55. Then route pressure hose

up to the hose mounting plate on the top arm. Refer

to Figure 55. Make sure there is no slack between

these two points. All excess pressure hose slack must

be collected between the top hose mounting plate on

the bearing housing arm and the pressure hose clip.

Refer to Figure 55.

IMPORTANT: The three arm bolts should always

be tightened first and torqued to 275 inch pounds

(31.46 Nm). Then tighten the three inner bolts and

torque to 150 inch pounds (17.16 Nm).

NOTE: If a bearing failure should occur, a new

bearing housing assembly should always be used.

The bearings and seal are not serviceable parts.

Make sure the new bearing housing seal is packed

with lubrication in all grooves before installation. If

not, lubricate seal.

Содержание HWFB61QN1102

Страница 2: ......

Страница 14: ...12 801683 Section 2 Introduction Copyright Alliance Laundry Systems LLC DO NOT COPY or TRANSMIT Notes ...

Страница 70: ...68 801683 Section 4 Grounding Copyright Alliance Laundry Systems LLC DO NOT COPY or TRANSMIT Notes ...

Страница 138: ...136 801683 Section 6 Adjustments Copyright Alliance Laundry Systems LLC DO NOT COPY or TRANSMIT Notes ...