801683

103

Section 5 Service Procedures

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

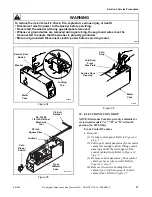

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

• Motor not grounded! Disconnect electric power before servicing motor.

W485

WARNING

47. BELT

a. While supporting the lower access panel,

remove two screws from bottom edge of panel

and remove panel. Refer to

b.

Front Control Washers –

(1) Remove control panel. Refer to

.

(2) Remove two screws holding front of

cabinet top to top front edge of control

cabinet front. Refer to

.

Rear Control Washers –

(1) Using the special tool, No. 318P4, remove

dispenser drawer. Refer to

.

(2) Open loading door. Carefully remove wire

clamp ring from groove with small flat

blade screwdriver. Spring is in the

6 o’clock position. Refer to

.

NOTE: To avoid damage to spring, use screwdriver

on wire clamp ring to right or left of spring.

(3) Grasp loading door seal lip. Refer to

, Step “1”.

NOTE: To avoid damage to door seal, DO NOT use

pliers or sharp objects to grasp the door seal lip. If

lip is damaged, seal will leak.

(4) Using a circular motion, pull seal up

, Step

“2”), and down (

, Step “3”).

(5) When seal releases from lip of front panel,

pull out and remove the seal from front

panel around door opening. Refer to

, Step “4”.

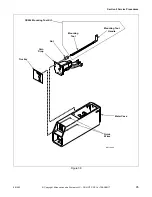

(6) While supporting the front panel assembly,

remove the two bottom front corner screws.

Refer to

. Remove front panel

(with loading door attached) away from

washer as far as wire permits.

(7) Unplug wire harness from both the door

latch switch and from the door switch.

Refer to

. Remove clips holding

wire harness and door seal hose along top

flange of front panel and remove front

panel.

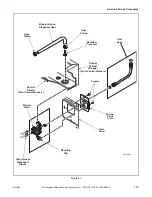

(8) Unlock and remove meter case service

door. Refer to

.

(9) Remove shoulder screw from inside meter

case.

(10) Remove two screws holding cabinet top to

front flange of each side panel. Refer to

.

(11) Remove security bolt (if present) from left

rear corner of cabinet top. Refer to

.

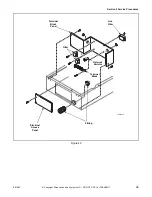

c. If area or space permits, lift cabinet top to a

vertical position by hinging it on the rear

hinges.

NOTE: To avoid damage to hinges, be sure to

support cabinet top with a small chain or something

similar.

d. Run belt off cylinder pulley while slowly

.

e. Remove belt from motor shaft.

NOTE: When installing belt, adjust belt tension as

follows:

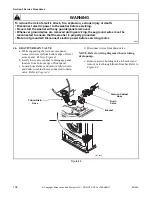

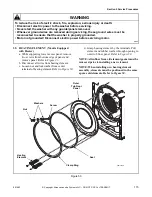

f. Working through the front access door opening,

place a locking pliers on the metal rod and

loosen the two adjusting bolts. Repeat

procedure to loosen the two pivot bolts. Refer

to

.

g. Pull down on motor to increase belt tension.

Use a Burroughs belt gauge to obtain proper

tension. Proper belt tension is obtained when

belt can be deflected approximately 1/4 inch

(6.35 mm) from normal position when

moderate pressure 50 to 60 pounds (22.68 to

27.22 Kg) is applied to a point midway between

pulleys. Refer to

h. After proper belt tension has been obtained,

tighten belt adjusting bolts firmly, then tighten

pivot bolts. Refer to

.

Содержание HWFB61QN1102

Страница 2: ......

Страница 14: ...12 801683 Section 2 Introduction Copyright Alliance Laundry Systems LLC DO NOT COPY or TRANSMIT Notes ...

Страница 70: ...68 801683 Section 4 Grounding Copyright Alliance Laundry Systems LLC DO NOT COPY or TRANSMIT Notes ...

Страница 138: ...136 801683 Section 6 Adjustments Copyright Alliance Laundry Systems LLC DO NOT COPY or TRANSMIT Notes ...