6

⚠

ATTENTION: The room must have a capacity of not less than 20 m

3

and must possess all the necessary ventilation

conditions, as described in Chapter 2 of this manual. These conditions will provide the necessary air flow to allow for

proper combustion (40 m

3

/h).

IT IS FORBIDDEN TO use the product in bedrooms and bathrooms.

IT IS FORBIDDEN TO use the product in spaces with another heating appliance already installed which does not have

its own system for air intake.

IT IS FORBIDDEN TO install the product near flammable materials.

IT IS FORBIDDEN TO set up the product on the floor made of combustible material unless it the protective plate of non-

flammable material is used.

IT IS FORBIDDEN TO use the product in explosive and potentially explosive atmospheres.

Installation

You must comply with all local and national laws and European standards in terms of installation, use, and

maintenance of the device

.

Placing of the device

Our product creates heat by bringing in the air necessary for combustion process directly from the environment that is

being heated.

For this reason, and because of basic safety for the furnace users, the device should always be installed inside an

adequately ventilated environment to ensure a steady flow of combustion air.

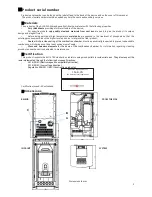

Therefore, it is necessary to install the air intake openings that are connected with the air outside (as shown in Figure

2.1)

In accordance with the provisions laid down in UNI 10683 standard, air intakes must have the following characteristics:

1.

Have to have internal cross-section of not less than 80 cm

2

;

2.

Have to be placed approximately at the level of the floor;

3.

They must be adequately protected by wire mesh or grate so that the minimum radius requirement for air flow is

not diminished;

4.

Have to be placed so that they are not covered in any way.

Adequate fresh air flow can also be provided using the opening to the next room, if the room is equipped with direct

ventilation and does not present a risk of fire, such as a warehouse, garage or storage, as required by the UNI10683

standard.

It is recommended to avoid placing the furnace in the rooms where there are devices which do not have a closed

system in relation to the environment or in the rooms where there are devices which may reduce the pressure in the room

itself in relation to the external environment, because it may mead to the problems with weak air intake for our product

(UNI 10683).

⚠

ATTENTION: It is forbidden to release the furnace combustion products into the shared pipe.

When checking the compatibility of the system, it is recommended to determine if the surface of support (floor) has

adequate load capacity (kg) to hold the weight of the product. If this is not the case, it is recommended to take appropriate

safety measures (for example, to use a panel for the distribution of freight).

When installing the furnace, it is advisable to set the appropriate distance from the wall to allow access to the back of

the furnace (we recommend at least 20 cm) and to the side (we recommend 80 cm). Such a space may be required, for

example, in order to allow adequate cleaning.

⚠

CAUTION: You might sense an unpleasant smell of paint when lighting the stove for the first time. If this happens,

keep the stove running at maximum power during the first few days to burn off the paint as quickly as possible and make

the unpleasant smell disappear. Make sure that room in which stove is installed is well ventilated.

Picture 2.1:An example of the necessary air opening

Never let the flammable materials get close or come into contact with the outer surfaces of the combustion chamber,

as these can reach extremely high temperatures when the product is in operation.

A

A