11

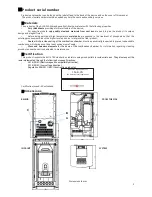

The control panel (display): use and functions

4.2.1

Display K100

The main frame

shows:

time and date, Chrono

activation, combustion

energy, heat energy,

functional condition, the

current room temperature,

set room temperature,

LEDs

Presentation

Explanation

Main Temp.

The current value of the room temperature

State

Functional condition of the furnace

Main Therm.

The set room temperature

Comb.Power

Combustion power

Heat.Power

Heating power

Time

Time

Chrono

The programmed work

Button

Function

P1

Exit from the menu/sub-menu

P2

Switching on and off (hold down for 3 seconds), resetting of errors (hold down for 3 seconds), Chrono

activation and deactivation

P3

Entering the User menu 1 /submenu, entering the User menu 2 (hold for 3 seconds), data storage

P4

Entry to the visualisation menu, increasing

P5

Entry to the visualisation menu, decreasing

Led

Function

Led

Function

Pellet shortage

The set room temperature has been

achieved

Air flow direction

Remote thermostat temperature

achieved (if remote thermostat is

connected)

4.2.2

Alarms

Description

System condition

Code

Safety error - safety thermostat: signals when the system is off

Block

Er01

Safety error - pressure control: signals only if the combustion fan is

turned on

Block

Er02

Shutting off in case the flue gas temperature is less than permitted

Block

Er03

Shutting off in case the flue gas temperature is higher than permitted.

Block

Er05

Pellet thermostat is activated

Block

Er06

Fan encoder error: No encoder signal

Block

Er07

Fan encoder error: failed combustion fan regulation

Block

Er08

The date and time are not correct due to a longer power outage.

Block

Er11

Ignition failed

Block

Er12

Power outage

Block

Er15

Error in communication - Display disconnected

Block

Er16

Error in the air flow regulator

Block

Er17

No more pellets

Block

Er18

Air flow sensor damaged.

Block

Er39

Minimal air flow during the check phase not achieved

Block

Er41

Maximal flow of air achieved (F40)

Block

Er42

Auger encoder error: No encoder signal

Block

Er47

Auger encoder error: failed auger regulation speed

Block

Er48

Module error I/O 12C

Block

Er52

Repair shop error. Informs that the planned period of operation has been

reached (after the pre-feeding): the system will stop only when it moves to

the work mode.

Block

Repair shop