Installation and Configuration

Ndrive HL User’s Manual

2-10

www.aerotech.com

2.4.3.1.

Brushless Motor Phasing

When configuring the Ndrive HL to run a non-Aerotech brushless motor, the motor leads

(A, B and C on TB101) must be correctly connected for proper operation. If an Aerotech

motor is used with Aerotech provided cabling, no motor phasing process is required.

If an Aerotech brushless motor is used with the Ndrive HL,

motor phase and HALL connections can be easily

determined by referring to the system interconnection

drawing in Figure 2-7.

Be sure to configure all axes with the Nparam.exe utility

before running the

A3200\Programs\Samples\MsetDebug.Pgm. See the

“Getting Started” section in the Nview help for

configuration information.

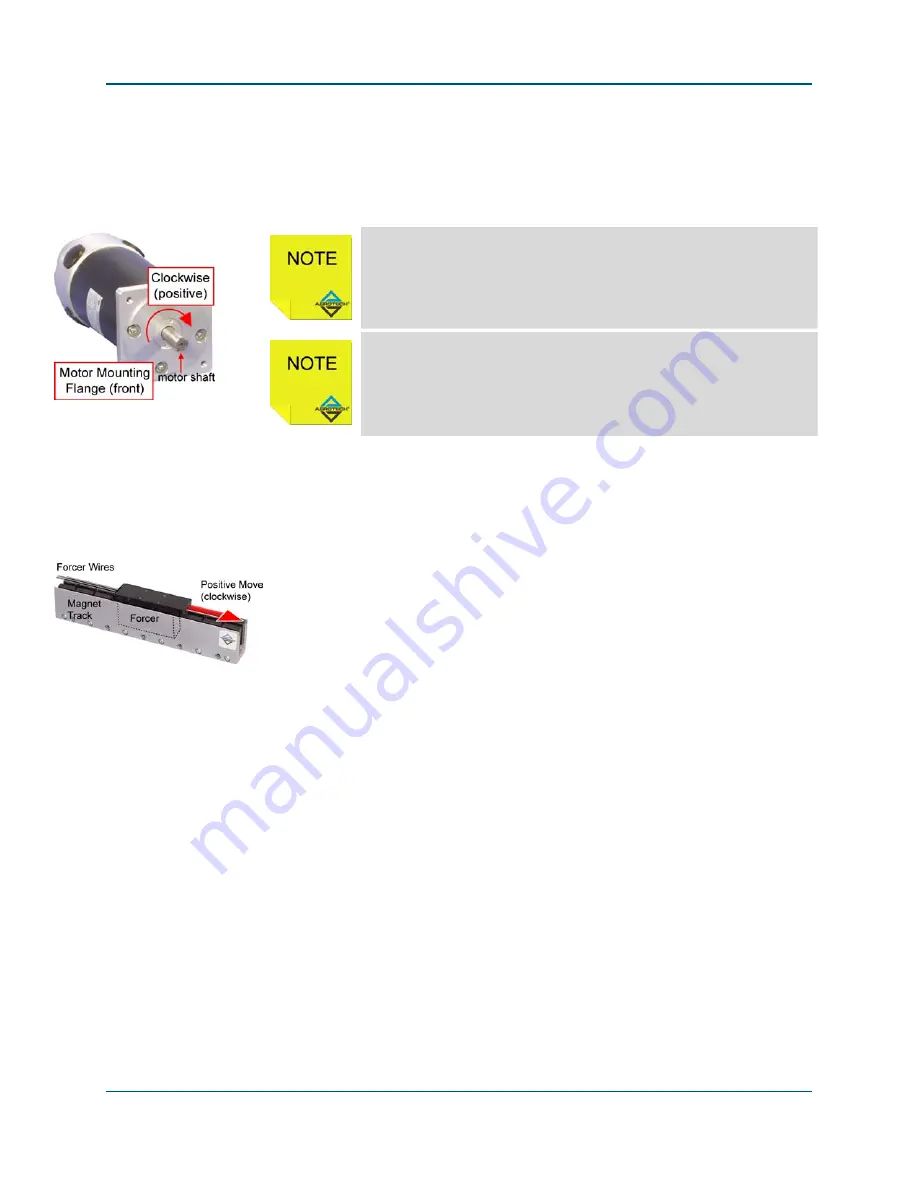

An AC brushless motor is correctly phased, when a positive motion command causes

clockwise (CW) motor rotation, as viewed looking at the motor from the front mounting

flange. This assumes a positive CntsPerMetricUnit/ CntsPerEnglishUnit

/CntsPerRotaryUnit axis parameter. This required phasing is determined by which motor

lead is connected to the ØA, ØB and ØC motor terminals.

Motor phasing is unrelated to the direction of motion commanded from within a motion

program. After correctly phasing the motor, you may reverse the motor direction when

commanding a positive move from a motion program, by negating the sign of the

CntsPerMetricUnit/CntsPerEnglishUnit/CntsPerRotaryUnit axis parameter.

Motor phasing may be determined by two methods. The first of which, is by actively

driving the motor open loop, under program control. The

A3200\Programs\Samples\MsetDebug.Pgm may be used for this purpose. The motor

phasing is correct when the program causes the motor to move in a positive direction, as

defined in Figure 2-13. Swapping any two motor lead connections will correct a reversed

motor rotation.

The second method is a non-powered method, whereby the motor is disconnected from

the controller and connected in the test configuration as defined in Figure 2-10 This will

identify motor (and Hall signal) leads A, B and C. These sequences and the generated

output motor phase voltages (motor output connections A, B, and C) are shown in

Figure

2-10. The voltages generated are made by moving the motor/forcer by hand in a positive

(CW) motion direction.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com