USER’S MANUAL

V-line 899x.xxx/LPG HYBRID

42

-

discharge sediments, water or other contaminants from the tank (containers of fuel) by means of

sludge pumps

13.

MAINTENANCE OF THE DISPENSER AND ITS INDIVIDUAL OPERATING

UNITS – MODULE FOR DISPENSING LPG

The user of the dispenser is obliged to operate the device safely, reliably and in economic way. First of all

he is obliged to:

–

appoint a worker responsible for the operation and technical conditions of the dispenser and its

individual components

–

ensure inspection, testing, repairs and maintenance by qualified methods

–

carry out records and file documents

ATTENTION!

All repairs of operating units can only be carried out by a service repair shop and their serviceman

with relevant authorisation.

Repairs, changes and dismantlings of undermentioned dispenser units depends of the perfect

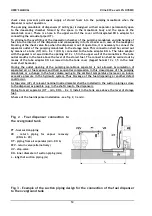

propane butane displacement with nitrogen from all space of dispenser hydraulic system.

Since even after the education of nitrogen from the dispenser its residues with minimum pressure

stay in the hydraulic system, it is necessary to come on very carefully at the service interventions.

Marking of space endangered with pressure expansion of residual nitrogen - see the enclosure

no. 7.

13.1.

LPG piston flow meter

The LPG meter unit consists of proper meter and integrated impulse detector. It is adjusted by the

producer. Only authorised specialist can handle the metering unit because the meter is officially sealed. If

the seals are damaged, it is necessary to carry out an official inspection and new official sealing.

A trained worker should follow the meter continuously to carry out necessary repairs immediately in case

of any defect. Constant accuracy of the adjusted meter is one million dm

3

at least for measured liquid

without mechanical impurities. It is recommended to check the accuracy of the meter after dispensing

such liquid gas quantity. The meter should be periodically inspected (calibrated) by a metrological office

according to relevant legal regulations - once per year at least.

The impulse sensor is not being repaired - the meter should only be replaced. New official authorisation

(sealing) must be carried out after its replacement.

13.2.

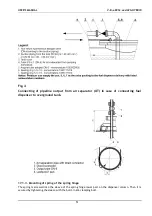

Differential valve

The valve is designed to keep the substance in liquid condition in the meter. It also damps pressure

shocks. Only uncompressible liquefied substance of pressure higher (appxm. by 0,1 MPa) than the

counterpressure of gaseous phase as generated by the spring pushing the differential piston into the valve

seat from the side of the gaseous phase allows to shift the valve cone of the differential piston off the

valve seat so that the flow through the valve is open.

All defects of the valve shall be repaired by a professional labourer.

The cover of the valve is protected by a seal of the producer or the service shop against unauthorised

intervention.

13.3.

Separator

The separator prevents the inlet of the gaseous phase into the meter.

The separator together with a filter, non-return valve, pressure-release valve and a safety valve for the

gaseous phase form one assembly unit.

ATTENTION!

The filter collects impurities for the substance being pumped. In case the discharge drops, it is

necessary to check the filter, clean or replace it.

Содержание V-line 899 LPG HYBRID Series

Страница 2: ......

Страница 26: ...USER S MANUAL V line 899x xxx LPG HYBRID 20 Pic 6 Pic 7 ...

Страница 29: ...USER S MANUAL V line 899x xxx LPG HYBRID 23 Pic 15 Pic 16 ...

Страница 30: ...USER S MANUAL V line 899x xxx LPG HYBRID 24 Pic 10 Scheme of inputs and outlets of the unit VAPORIX Control ...