USER’S MANUAL

V-line 899x.xxx/LPG HYBRID

40

10.6.

Dispensing nozzle

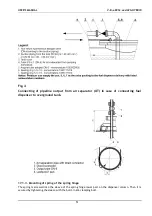

It is a terminal part of the dispenser by means of which fuels are dispensed. The dispensing nozzle

enables:

–

service dispensing - the rate of flow can be controlled up to its full stop by means of control lever

–

STOP function - the dispensing nozzle stops the flow if the tank is filled up

–

safety function - the dispensing nozzle stops the flow in case of unskilled handling or when the

nozzle falls out from the fuel tank filler

After both these safety actions the control lever shall be released to get it automatically back to its initial

position. The dispensing nozzle is a highly sensitive and complicated closing device. Therefore replacing is

recommended instead of repairing at the filling station. The nozzle is unscrewed from the hose adapter

while taking care not to lose the screen located in the nozzle. The screen shall be cleaned regularly

because the clogged screen may result in substantial reduction of fuel flow.

10.7.

V-belt of the pump

A swivelling bracket of the el. motor is used for tightening the pump V-belt. After replacing the fixing bolt

the motor can be shifted so that the V-belt has 10 to 12 mm sag if slightly pushed down by hand. Then the

bolt is retighten. The V-belt must satisfy the conductivity property according to

ISO 1813 and R044-001

.

The V-belt of identical dimensions and similar conductivity property shall be used for the replacement

of the existing V-belt.

The contact surfaces of V-belt pulleys shall be metal clean to provide earthing.

10.8.

Dismantling of covers

It is carried out in required scope during installation, routine maintenance, minor repairs and

modifications of electric or hydraulic parts.

The original location of covers must be held in remounting!

10.8.1.

Covering of MONO, DUO hydraulic modules.

To make the interior of hydraulics accessible the door shall be dismounted by unlocking, tilting and

slipping out.

To make the entire interior of the hydraulic module accessible it is necessary to dismantle the module

cover by loosening six M8 nuts, three on the column and three on the foundations. Four bolts positioned at

the upper part of the column shall be loosened for lifting the column cover off to make the junction box

accessible. Then the column can be tilted and slipped out.

Take care of the magnetic switch cable for

controlling the lifting of the dispensing nozzle.

10.8.2.

Covering of DUPLEX hydraulic module.

To make the interior of hydraulics accessible the door shall be dismounted by unlocking, tilting and

slipping out. The dismounting of the column covers is similar to MONO and DUO dispensers.

10.8.3.

Covering of counter case

Face covers are disassembled by unlocking the cover and lifting it upwards on hinges. The cover lifted is

screwed by means of the cover holder in the upper position.This allows the access to the electronic

counter and other components located in the box.

Any handling the electric and electronic parts may only be carried out by a specialist who is responsible

for the safety of the equipment. The IP 54 protection may not be affected during the counter case

handling.

It is necessary to check the gasket prior to remounting the cover. Damaged gasket shall be replaced.

10.8.4.

Dismounting of the metering unit

Dismount the covers, unscrew the bolts connecting the meter to the joining piece. Disconnect the flange

connection to electromagnetic valve, dismount the bolts of the integrated detector and remove it from

the meter. Reverse procedure is used for remounting the meter.

ATTENTION!

THERE IS EXPLOSION HAZARD WHEN USING A NON-CONDUCTIVE V-BELT!!!

Содержание V-line 899 LPG HYBRID Series

Страница 2: ......

Страница 26: ...USER S MANUAL V line 899x xxx LPG HYBRID 20 Pic 6 Pic 7 ...

Страница 29: ...USER S MANUAL V line 899x xxx LPG HYBRID 23 Pic 15 Pic 16 ...

Страница 30: ...USER S MANUAL V line 899x xxx LPG HYBRID 24 Pic 10 Scheme of inputs and outlets of the unit VAPORIX Control ...