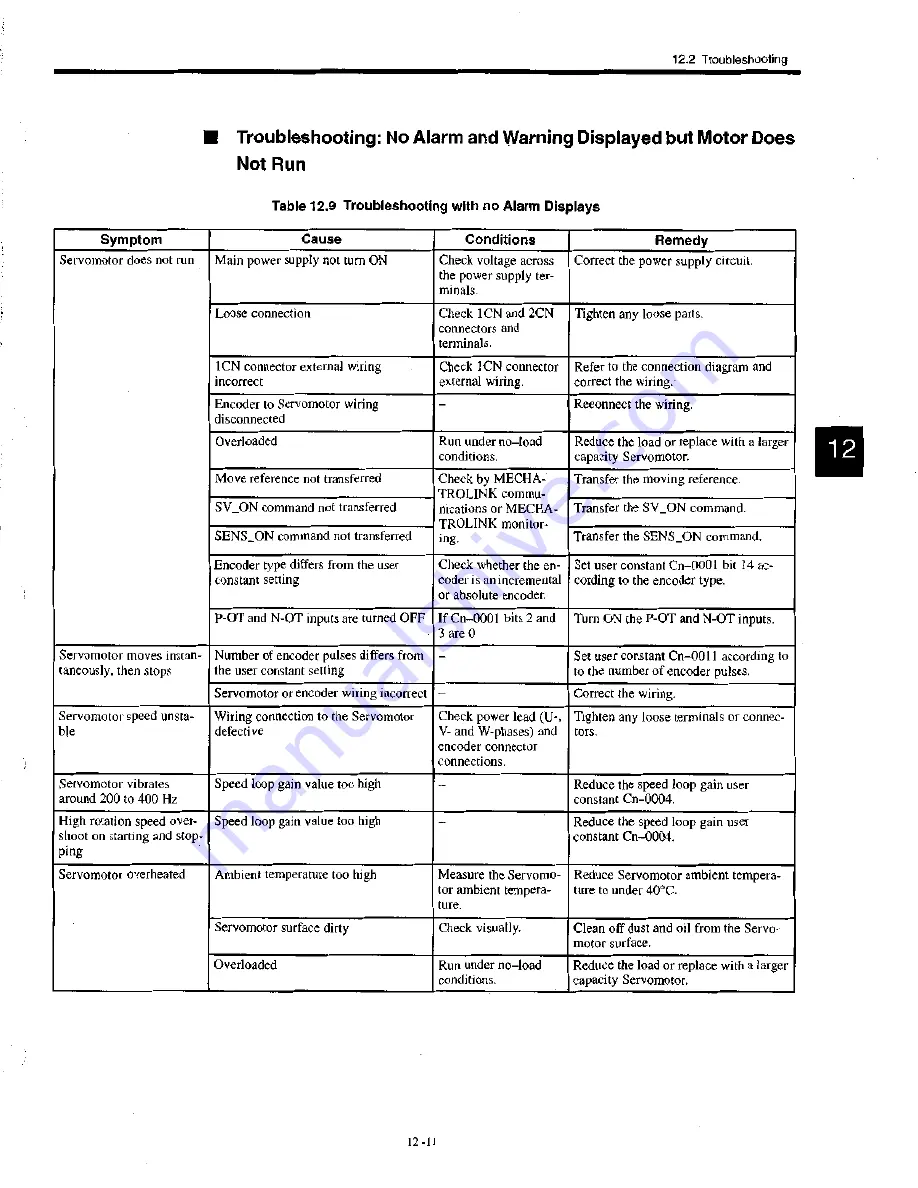

12.2 Troubleshooting

Symptom

Cause

Conditions

Remedy

Servomotor does not run

Main power supply not turn ON

Check voltage across

the power supply ter-

minals.

Correct the power supply circuit.

Loose connection

Check 1CN and 2CN

connectors and

terminals.

Tighten any loose parts.

1CN connector external wiring

incorrect

Check 1CN connector

external wiring.

Refer to the connection diagram and

correct the wiring:

Encoder to Servomotor wiring

disconnected

—

Reconnect the wiring.

Overloaded

Run under no—load

conditions.

Reduce the load or replace with a larger

capacity Servomotor.

Move reference not transferred

Check by MECHA-

TROLINK commu-

nications or MECHA-

TROLINK monitor-

ing.

Transfer the moving reference.

SV_ON command not transferred

Transfer the SV_ON command.

SENS_ON command not transferred

Transfer the SENS_ON command.

Encoder type differs from the user

constant setting

Check whether the en-

coder is an incremental

or absolute encoder.

Set user constant Cn-0001 bit 14 ac-

cording to the encoder type.

P-OT and N-OT inputs are turned OFF

If Cn-0001 bits 2 and

3 are 0

Turn ON the P-OT and N-OT inputs.

Servomotor moves instan-

taneously, then stops

Number of encoder pulses differs from

the user constant setting

—

Set user constant Cn-0011 according to

to the number of encoder pulses.

Servomotor or encoder wiring incorrect —

Correct the wiring.

Servomotor speed unsta-

ble

Wiring connection to the Servomotor

defective

Check power lead (U-,

V- and W-phases) and

encoder connector

connections.

Tighten any loose terminals or connec-

tors.

Servomotor vibrates

around 200 to 400 Hz

Speed loop gain value too high

—

Reduce the speed loop gain user

constant Cn-0004.

High rotation speed over-

shoot on starting and stop-

ping

Speed loop gain value too high

—

Reduce the speed loop gain user

constant Cn-0004.

Servomotor overheated

Ambient temperature too high

Measure the Servomo-

tor ambient tempera-

ture.

Reduce Servomotor ambient tempera-

ture to under 40°C.

Servomotor surface dirty

Check visually.

Clean off dust and oil from the Servo-

motor surface.

Overloaded

Run under no—load

conditions.

Reduce the load or replace with a larger

capacity Servomotor.

■

Troubleshooting: No Alarm and Warning Displayed but Motor Does

Not Run

Table 12.9 Troubleshooting with no Alarm Displays

12-11