136

CHAPTER2 PROFIBUS Unit

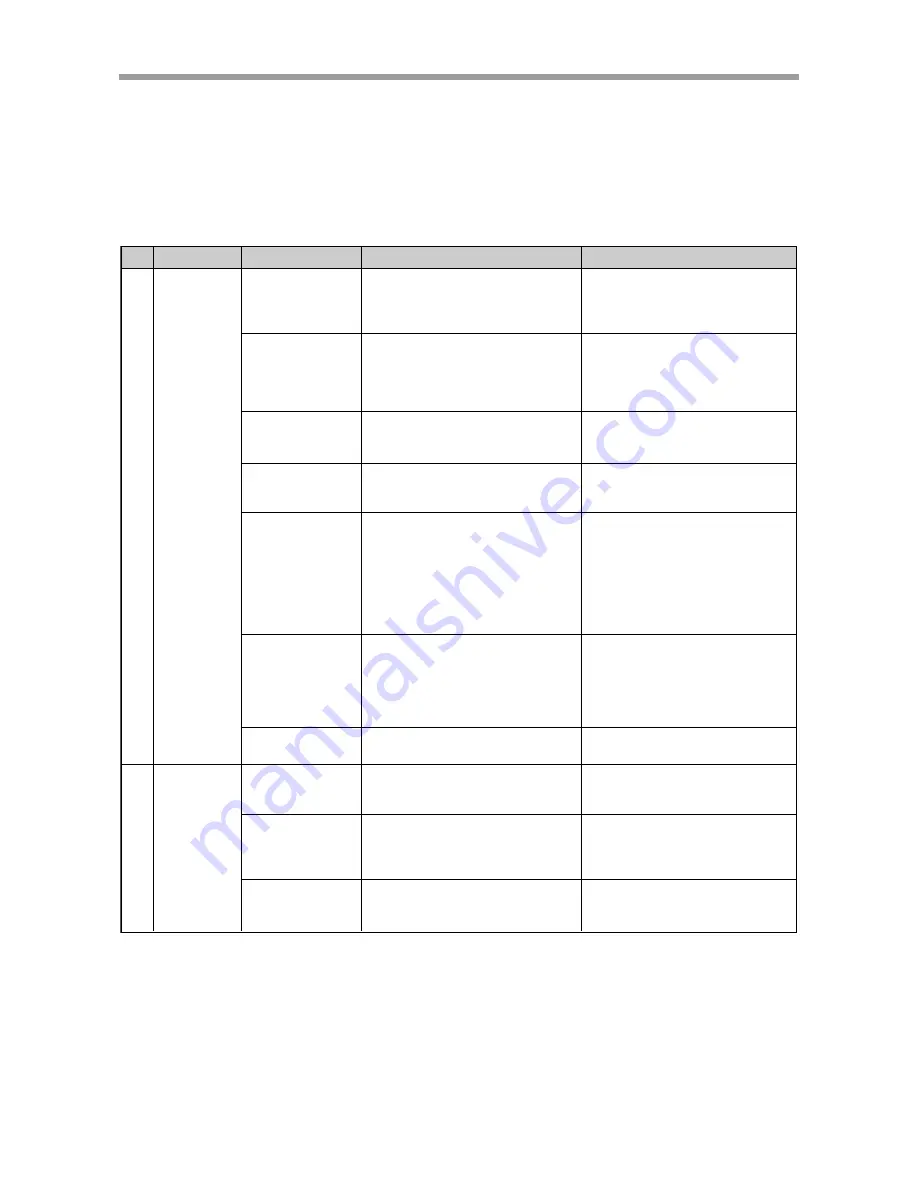

2-15 Troubleshooting

Check the following items if any problems occur during operation. Also, refer to “Trouble-

shooting” in the controller instruction manual and always refer to the section on trouble-

shooting in the master station sequencer (PLC) instruction manual. If the following items

do not eliminate the problem, promptly contact your Yamaha dealer or Yamaha for assis-

tance.

Checkpoints

• Check if PROFIBUS cable is not

connected, is miswired, or wires are

broken.

• Refer to “2-5-1 Validating the

PROFIBUS unit”, and check that the

PROFIBUS unit is properly validated.

• Refer to “2-5-2 Setting the station

address” and check the station

address.

• Connect the HPB and check for an

alarm.

• Check if the status LED is lit in red.

• Check the PROFIBUS cable wiring.

• Check the PROFIBUS cable

installation.

• Replace the PROFIBUS unit.

• Check Qn+1.7 status.

• Check if set to emergency stop at HPB

or external parallel I/O.

• Connect the HPB and check the alarm

that was issued.

• Status LED is lit up in red.

Remedy

• Correctly repair any miswirings or

unconnected wiring. Replace the

cable if broken.

• Validate the PROFIBUS unit, and

turn on the controller power again.

• Reset the station address correctly,

and turn on the controller power

again.

• Refer to the controller instruction

manual and troubleshoot according to

the particular alarm.

• Repair the wiring.

• Reinstall the PROFIBUS unit away

from the source of noise

(motor/power lines.)

• If this solves the problem, replace the

PROFIBUS unit.

• To turn on the servo (servo-on) set

Qn+1.7 to ON.

• Cancel emergency stop on the HPB

or external parallel I/O in order to set

the servo to on (servo-on).

• Refer to the controller instruction

manual and troubleshoot per the

particular alarm.

No.

1

2

Causes

PROFIBUS

cable not

correctly

connected.

PROFIBUS unit

is not validated

so cannot be

identified from

controller.

Station address

setting is

incorrect.

Alarm occurring

on controller.

PROFIBUS

cable length does

not meet

specifications for

the PROFIBUS,

or a terminating

resistor is not

connected.

PROFIBUS

cable is in

proximity to a

noise source such

as motor/power

lines.

PROFIBUS unit

is defective.

Set to emergency

stop with Qn+1.7

at OFF.

Set to emergency

stop from HPB

or external

parallel I/O.

Controller alarm

was issued.

1)

2)

3)

4)

5)

6)

7)

1)

2)

3)

Symptom

When using

the master

station

sequencer

line test

function,

unable to

verify from

the master

station

sequencer

(PLC), that

the robot

controller is

correctly

connected to

the

PROFIBUS

system.

Servo won’t

turn on.

(continued to next page)