11. ELECTRIC SYSTEM

11-9

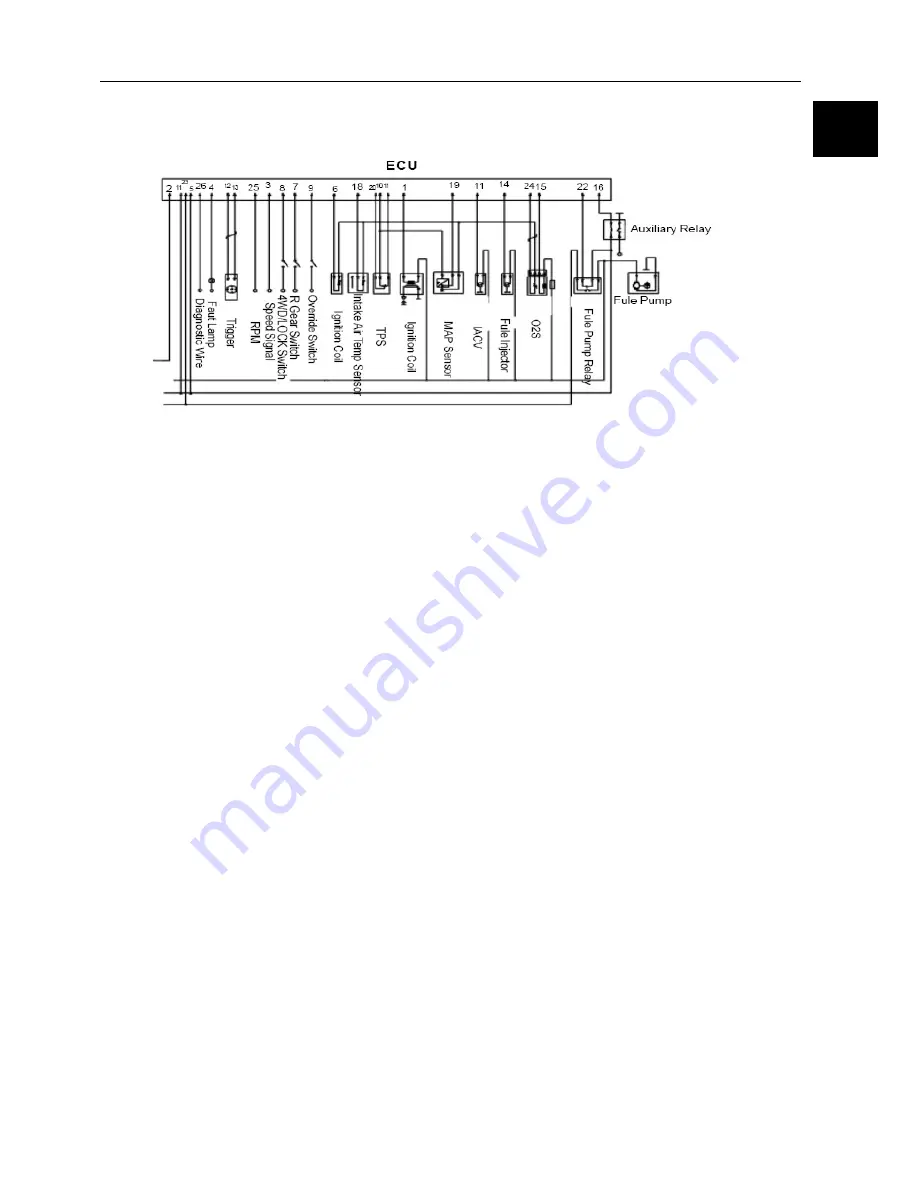

ELECTRONIC FUEL INJECTION SYSTEM

DIAGRAM

ELECTRONIC FUEL INJECTION SYSTEM

MAINTENANCE NOTICE

●

USE QUALITY COMPONENTS FOR SERVICE, OR ELSE IT

CANNOT GUARANTEE THE ELECTRONIC FUEL INJECTION

NORMAL OPERATION.

●

IN THE COURSE OF MAINTENANCE, NEVER TRY TO

BREAK DOWN THE ELECTRONIC PARTS.

●

IN THE COURSE OF MAINTENANCE, THE ELECTRONIC

COMPONENTS MUST BE HANDLED CAREFULLY.

●

WHEN CUT DOWN OR CONNECT UP PLUG

CONNECTOR,YOU MUST TURN OFF THE IGNITION SWITCH,

OR ELSE THE ELECTRONIC FUEL INJECTION COMPONENTS

WILL BE DAMAGED.

●

WHEN TAKE DOWN THE ELECTRIC FUEL PUMP, DONOT

ENERGIZE THE FUEL PUMP, IT CAN GENERATE SPARK AND

CAUSE FIRE.

●

FUEL PUMP NOT PERMITTED DO OPERATION TEST

UNDER DRY STATE OR IN WATER.OR ELSE WILL SHORTEN

IT’S LIFE. BESIDES,THE OIL FUEL PUMP TWO EXTREMES

CANNOT REVERSE CONNECTION.

●

ELECTRONIC FUEL INJECTION SYSTEM FUEL SUPPLY

PRESSURE IS HIGH(AROUND 300kPa),THE FUEL PIPE ALL

APPLY HIGH PRESSURE RESISTANCE PIPE,SO DO NOT

DISMANTLE THE PIPE WHEN THE FUEL SYSTEM NEEDED TO

BE REPAIRED,YOU HAVE TO DO FUEL PIPE PRESSURE

RELIEF BEFORE DISMANTLE THE OIL PIPE.PRESSURE

RELIEF METHOD IS AS FOLLOWING:

REMOVE FUEL PUMP RELAY,STARTING THE ENGINE AND

LET IT IDLE , UNTILL THE ENGINE DIES ITSELF.

FUEL PIPE’S DISMANTLE AND FUEL FILTER’S

REPLACEMENT SHOULD BE CARRY ON BY PROFESSIONAL

PERSON IN WELLVENTILATED PLACE.

●

WHEN INSPECTING THE IGNITION SYSTEM,ONLY IF

NECESSARY,DO SPARK TEST,AND SHOULD BE AS FAST

AS POSSIBLE, DONOT OPEN AIR SAMPER WHEN TESTING,

OR ELSE PLENTY OF UNBURNED FUEL WILL ENTER THE

VENT-PIPE AND DAMAGE THE TRIPLET CATALYST.

●

IDLE SPEED REGULATION COMPLETELY CARRY OUT BY

ELECTRONIC FUEL INJECTION SYSTEM,THROTTLE VALVE

GUN LIMIT SCREW ALREADY SETTED WHEN IT LEAVE THE

FACTORY,IT INITIAL POSITION CANNOT BE CHANGED

EASILY.

●

WHEN INSTALLING THE BATTERY, THE POSITIVE AND

THE GROUND CANNOT BE INSTALLED WRONG. THIS

SYSTEM APPLYS NEGATIVE GROUND.

●

WHEN ENGINE RUNNING,DON’T UNHOOK THE BATTERY

CABLE.

●

BEFORE CARRY OUT ELECTRONIC WELDING ON THE

VEHICLE,YOU ARE REQUIRED TO UNHOOK THE BATTERY

POSITIVE TERMINAL, NEGTIVE TERMINAL AND ECU.

●

DONOT USE METHOD IMPALE LEAD CUTICULAR TO TEST

COMPONENTS’S INPUT AND OUTPUT ELECTRICAL SIGNAL.

●

SET UP ENVIRONMENTAL PROTECTION

CONSCIOUSNESS. TREATING THE WASTE AFTER

MAINTENANCE.

11

Summary of Contents for XY500UTV

Page 1: ......

Page 2: ...Service Manual XY500UTV XY500LUTV XY500UE XY500UEL 4 4 ZHEJIANG XINYANG INDUSTRY CO LTD ...

Page 16: ...1 SERVICE INFORMATION 1 13 Cables Pipes Cable Routing 1 ...

Page 17: ...1 SERVICE INFORMATION 1 14 ...

Page 18: ...1 SERVICE INFORMATION 1 15 Carburetor Condition 1 ...

Page 19: ...1 SERVICE INFORMATION 1 16 Carburetor Condition EFI Condition ...

Page 20: ...1 SERVICE INFORMATION 1 17 Carburetor Condition 1 ...

Page 21: ...1 SERVICE INFORMATION 1 18 ...

Page 41: ...2 VEHICLE BODY MUFFLER 2 20 Description of visible parts ...

Page 44: ......

Page 66: ...4 COOLING AND LUBRICATIING SYSTEM 4 2 Cooling System Illustration 4 ...

Page 114: ...6 ENGINE REMOVAL INSPECTION INSTALLATION 6 29 Primary and Secondary Sheave 6 ...

Page 225: ......