8 FRONT WHEEL, FRONT BRAKE

,

SUSPENSION

,

STEERING

8-2

Troubleshooting Heavy

Steering

●

Steering bearing is damaged or worn

●

Inner & outer bearing races are damaged,

worn or stepped

●

Steering stem is distored

●

Tire pressure is too low

●

Worn tire

Shaking Steering Wheel

●

Steering wheel is not well tightened

●

Steering stem is loosened or not well installed

●

Mount seat, steering wheel is not well tightened

●

Bearing is damaged

●

Right and left shock absorbers are not matched

●

Deflected tires

●

Deformed frame

●

Worn tiers

●

Shaking of wheel bearing

Vibration of Front Wheel

●

Wheel rim distorted

●

Faulty wheel bearing

●

Faulty tire

●

Improper balance of wheels

●

Improper tightening of wheel axle

Wheel Cannot Turn Freely

●

Faulty wheel bearing

●

Front wheel axle is bended

●

Brake drag

●

Faulty steering structure

Front Suspension is Too Soft

●

Weakened front shock absorbers

●

Tire pressure is too low

Front Suspension is Too Hard

●

Front shock absorber is bended

●

Tire pressure is too high

Noise with Front Absorbers

●

Faulty front shock absorbers

●

Loosened tightening parts of front

absorbers

Poor Brake Efficiency

●

Faulty brake adjustment

●

Stained brake disc

●

Worn brake shoes

●

Air in brake hose

Summary of Contents for XY500UTV

Page 1: ......

Page 2: ...Service Manual XY500UTV XY500LUTV XY500UE XY500UEL 4 4 ZHEJIANG XINYANG INDUSTRY CO LTD ...

Page 16: ...1 SERVICE INFORMATION 1 13 Cables Pipes Cable Routing 1 ...

Page 17: ...1 SERVICE INFORMATION 1 14 ...

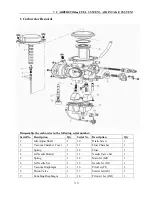

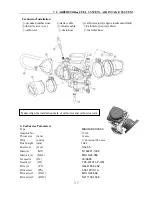

Page 18: ...1 SERVICE INFORMATION 1 15 Carburetor Condition 1 ...

Page 19: ...1 SERVICE INFORMATION 1 16 Carburetor Condition EFI Condition ...

Page 20: ...1 SERVICE INFORMATION 1 17 Carburetor Condition 1 ...

Page 21: ...1 SERVICE INFORMATION 1 18 ...

Page 41: ...2 VEHICLE BODY MUFFLER 2 20 Description of visible parts ...

Page 44: ......

Page 66: ...4 COOLING AND LUBRICATIING SYSTEM 4 2 Cooling System Illustration 4 ...

Page 114: ...6 ENGINE REMOVAL INSPECTION INSTALLATION 6 29 Primary and Secondary Sheave 6 ...

Page 225: ......