12

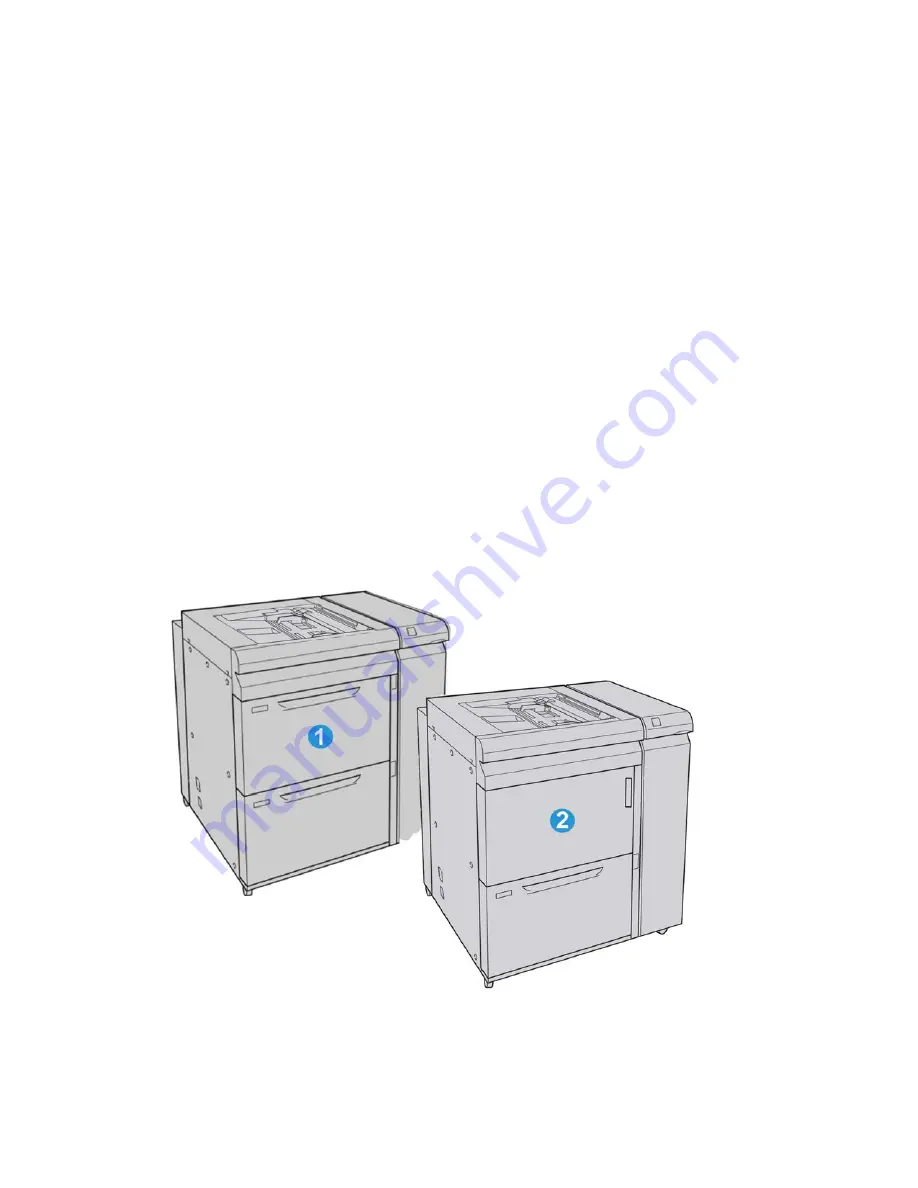

Oversized High Capacity

Feeder (OHCF), 1 or 2 trays

(Trays 6/7)

The Oversized High Capacity Feeder (OHCF) is available in a 1-tray or 2-tray option. The

OHCF feeds a variety of stock sizes, including standard and oversized stock up to 13 x

19.2 in./330.2 x 488 mm. Each tray holds 2,000 sheets.

12-1

Xerox

®

Color J75 Press

User Guide

Summary of Contents for Color J75 Press

Page 1: ...Xerox Color J75 Press User Guide Version 1 0 February 2013 702P00985...

Page 22: ...Xerox Color J75 Press 1 12 User Guide Product overview...

Page 24: ...Xerox Color J75 Press 2 2 User Guide Where to find help...

Page 116: ...Xerox Color J75 Press 9 22 User Guide Maintenance...

Page 158: ...Xerox Color J75 Press 10 42 User Guide Problem solving...

Page 316: ...Xerox Color J75 Press vi User Guide Index...

Page 317: ......

Page 318: ......