1726 North Ballard Road - Appleton, WI 54911 - 920.991.9082

Technical Support 800.238.8739 - [email protected]

PTM30112-G

12/07/2012

W

E

CRUSH

HAZARD

CUTTING

HAZARD

CRUSH

HAZARD

CRUSH

HAZARD

FALLING

HAZARD

CRUSH

HAZARD

PINCH

HAZARD

PUNCTURE

HAZARD

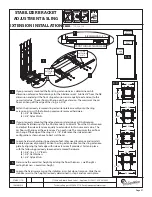

A

B

E

C

F

D

C

DOWEL

S

WALL

PO

C

KET

B

WALL

FA

S

TENER

S

PIN

E

WALL

E

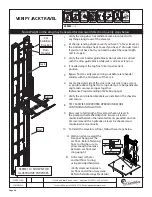

2

1

3

UNI-

S

TRUT

A

TTENTION

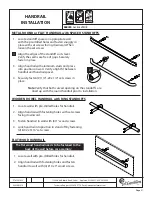

Verify clearance between car fl oor and all hoistway walls. Refer to fi eld drawings for details.

Individual car layouts may be diff erent; however, always treat the rail wall as the

B

wall during as-

sembly. Verify handrail type. Flat wood handrails must be installed before car assembly (reference

INTERIOR CAR FIXTURES page).

NOTE

We recommend the following tools should be available:

Wallboard

R

oll Lifter -

R

ubber Mallet -

D

rill - Level -

S

crew

D

river

S

et

Step

Insert provided dowels into

pre-drilled holes along

the top of the walls (wall

B [or rail wall]

will have

fasteners already attached to

the bottom). Insert dowels

into pre-drilled holes along

the top and bottom of post(s)

and pocket(s) if provided,

and opposing wall if

opposite opening layout.

Step 2

Warping before

installation may occur. To

correct the warping, place

provided shims between the

outside wall and the uni-strut

as necessary to correct the

warp. Verify the uni-struts are

securely fastened to the walls.

Step

The COP must be installed

into the wall prior to car

assembly. Using the provided

conduit clips & hardware,

secure the COP conduit to

the upper outside car wall for

easy access during cartop box

installation.

1

2

3

F

RA

MELE

SS

CAR

ASS

EMBLY

S

E

R

IE

S

:

015 - 016 - 018 - 115 - 116 - 118

Page 32