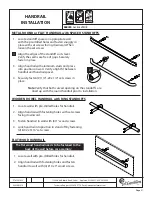

1726 North Ballard Road, Suite 1 - Appleton, WI 54911 - 920.991.9082

Technical Support 855.804.5774 - [email protected]

PTM30133-G

22 MAR 2018

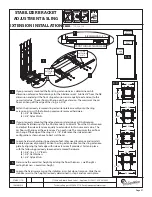

W

E

GUIDE

BLOCK

PIN

GUIDE

BLOCK

INSTALLATION

CLAMP

SLING

UPRIGHT

SLING

UPRIGHT

CROSS

ANGLES

UPRIGHT

CROSS

ANGLES

CRUSH

HAZARD

CUTTING

HAZARD

FALLING

HAZARD

CRUSH

HAZARD

PINCH

HAZARD

CAR STABILIZER

BRACKETS NOT

SHOWN

FOR CLARITY

UNIT DEPICTED WITH ALL SLING EXTENSION

OPTIONS SHOWN. EXTENSION LAYOUT MAY

CHANGE DEPENDING ON APPLICATION.

NOTE:

THERE MUST BE A SLIGHT GAP BETWEEN BOTH

UPRIGHT CROSS ANGLES. IF THE INSTALLATION

CLAMPS ARE FASTENED TIGHT AGAINST EACH

OTHER THE SLING WILL NOT SLIDE FREELY IN THE

RAIL SYSTEM.

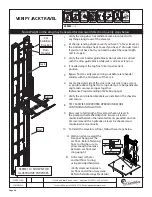

Verify all sling extensions are on or inserted in the sling before bringing sling into the hoistway.

1.

2.

3.

4.

6.

5.

2, 3

6

4

Note:

The top of the sling base should

be 2 “below the lowest fl oor landing.

Note:

Verify sling uprights are true to

the rail. Ratchet strap may assist in this.

SERIES :

115, 116, 118

Insert guide block pins into the (4) pin sleeves located on the

inside of the sling. Verify pins fl anges are tight to sling tube.

(Locate the two (2) adjustable pins at the top of the sling).

Using the provided (8) - 1/4”-28 set screws securely fasten the

guide block pins in position.

Press (4) guide blocks in position on the guide block pins.

Verify the guide block holes are all off set in the correct

orientation as shown with the thick part towards the rail

backing once installed.

Bring the sling halves into the hoistway and block up as

required.

Set the right and left sides of the sling in position in the rail.

Fasten the right and left halves together with the installation

clamps using the following provided hardware:

(2) - 3/8”-16 x 1-1/4” Hex Bolts

(2) - 3/8” Nylock Nuts

SLING ASSEMBLY AND

SAFETY INSTALLATION

Page 24