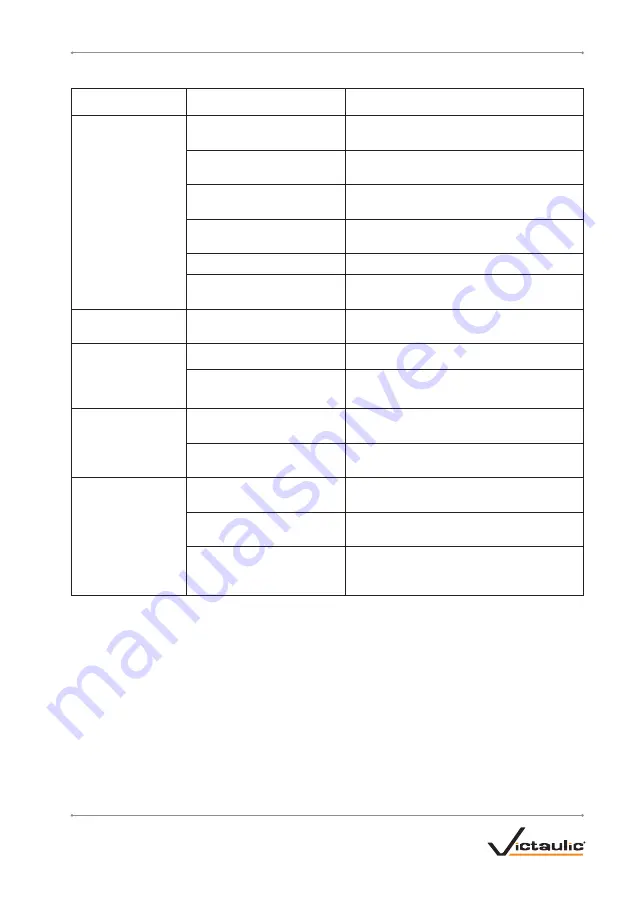

PROBLEM

POSSIBLE CAUSE

SOLUTION

Pipe flare is excessive.

Pipe support is adjusted too high for

long pipe.

Refer to the “Grooving Long Pipe Lengths” section.

Tool is tilted forward (out of level) while

grooving long pipe.

Refer to the applicable “Tool Setup” section.

Incorrect pipe support positioning of long

pipe. Pipe is “over-tracking.”

Move the pipe support to the right. Refer to the “Grooving Long

Pipe Lengths” section.

Pipe stabilizer is adjusted too far inward.

Back off the pipe stabilizer to the furthest point where it still

stabilizes the pipe effectively.

Ram speed is not set correctly.

Refer to the “Ram Speed Control Valve Adjustment” section.

Excessive ram pressure.

Reduce ram pressure by turning the selector valve on the front of

the tool to the

“BLACK”

setting.

Larger diameter pipe sways or

vibrates from side to side.

Incorrect pipe stabilizer adjustment.

Move the pipe stabilizer in or out until the pipe rotates smoothly.

The tool will not groove the

pipe, or the tool comes up to

operating pressure excessively

slowly.

Air is present in the hydraulic system.

Refer to the “Air Bleeding” section.

Pipe is beyond the wall thickness or pipe

yield strength capacity of the tool.

Refer to the applicable “Tool Rating and Roll Selection” section.

Pipe groove diameters do not

meet Victaulic specifications.

Groove diameter stop is not adjusted

properly.

Refer to the “Groove Diameter Stop Adjustment” section.

Pipe is beyond the wall thickness or pipe

yield strength capacity of the tool.

Refer to the applicable “Tool Rating and Roll Selection” section.

The “A” Gasket Seat or “B”

Groove Width dimensions

do not meet Victaulic

specifications.

Upper roll bearing is not lubricated

adequately.

Refer to the “Maintenance” section.

Incorrect upper roll, lower roll, or both

installed on the tool

Install the correct rolls. Refer to the applicable “Tool Rating and Roll

Selection” section.

Pipe not inserted fully onto the lower roll,

or pipe is not tracking properly.

Make sure pipe is against the lower-roll backstop flange. Refer to

the “Grooving Long Pipe Lengths” section for proper pipe stand

positioning.

In the event of tool malfunction outside the scope of the troubleshooting section, contact Victaulic for

assistance.

TROUBLESHOOTING (CONTINUED)

TM-VE268_47

REV_H

TM-VE268

/ Operating and Maintenance Instructions Manual

Summary of Contents for VE268

Page 2: ......