ADVANCED SYSTEM OPERATION

Section 9-18

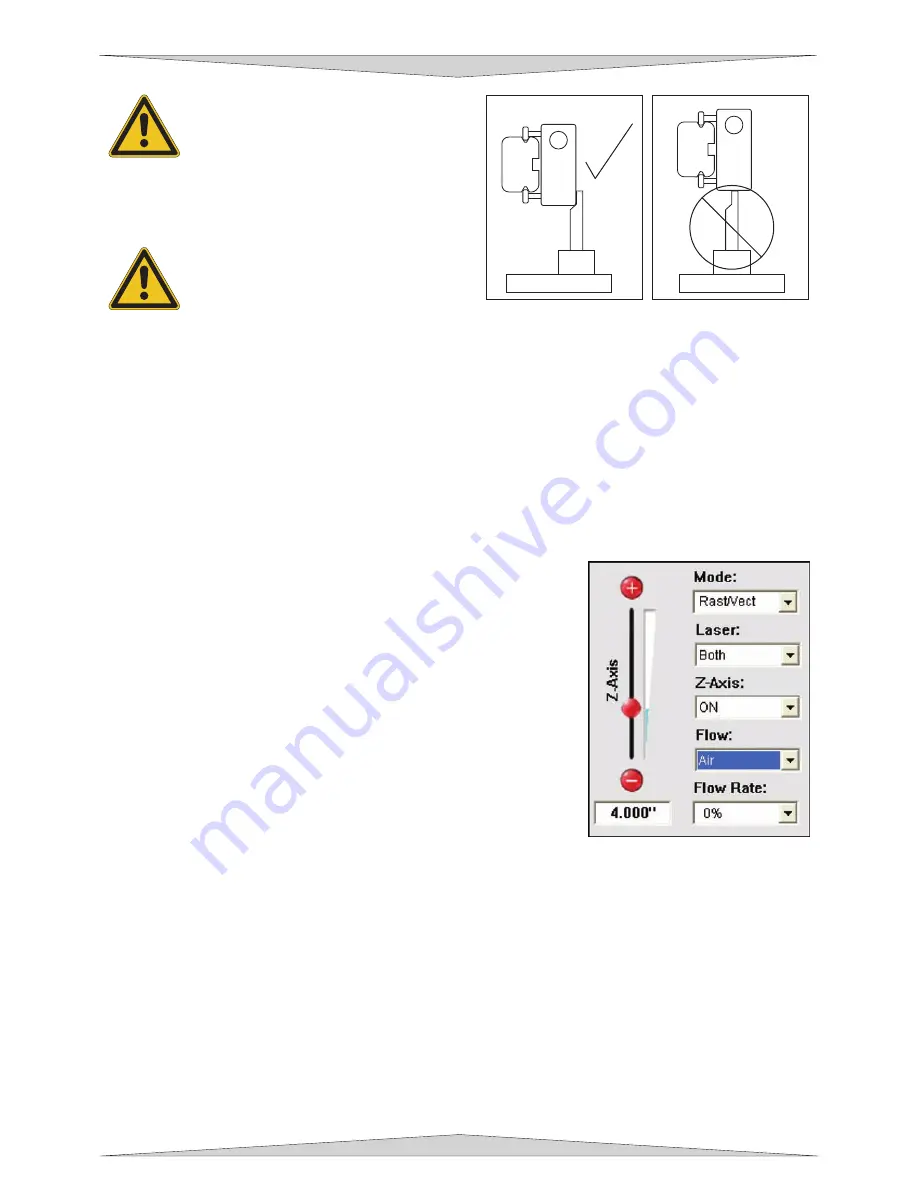

WARNING:

To avoid damage to the

focus lens, avoid positioning the focus

tool underneath the focus carriage.

Sometimes it is desirable to be slightly

out of focus when engraving or cutting. It widens the

beam at the surface of the material to soften the image

or create a wider cut line.

WARNING

: DO NOT engrave or cut too

far out of focus, as this can be a potential

fire hazard. A maximum of .05 inches

above or below precise focus should be

the absolute limit.

From a physics point of view, there is no difference between raising the Z-axis table a specified distance

from the focal point and lowering the table the same distance from the focal point. However, from an

applications point of view, we recommend lowering the Z-axis table when intentionally

RASTER

ENGRAVING

out of focus and raising the Z-axis table when intentionally

VECTOR CUTTING

out of

focus.

NOTE:

This focusing method can be done in a variety of ways. By using the Keypad, Universal Control

Panel or a combination of both. The Keypad was used in this method because you have easier access to

the engraving system. A combination of the UCP and Keypad or only using the UCP may require more

then one person to complete the Focus Tool Method.

2. Material Thickness (Z-Axis) Method

Focus on

TOP

of the engraving table, not the material, using the focus

tool as mentioned in the previous method. Create your graphic and

go to File and select Print from the drop down list. On the Print

window that opens select the laser system you own and then click the

PROPERTIES button. Click on the Manual Control Tab. To the right

hand side of the printer driver you will see a vertical sliding bar named

Z-Axis with plus (+) and minus (-) buttons. In order to active this

feature select ON from the drop down list that is labeled Z-Axis that is

located next to the Z-Axis vertical sliding bar. In the blank area

underneath the minus (-) button type the material thickness of the

object being engraved. Focusing using this method is now complete.

Make any necessary changes to your Manual Control driver as

desired. At this point place the material in the appropriate location on

the engraving table according to your graphic placement. Click the

OK button located on the bottom right corner of the printer driver to

send the file to the laser system. Start the Universal Control Panel,

your laser system, and start printing your job.

Periodically check if the Z POSITION method is calibrated with your focus tool. Since your focus tool is

your absolute reference, make sure that you do not lose it.

Summary of Contents for PLS3.60

Page 8: ......

Page 20: ...SAFETY Section 1 12 ...

Page 21: ...Part 1 Initial Setup ...

Page 22: ......

Page 30: ...INSTALLATION Section 2 10 ...

Page 44: ...GRAPHICS SOFTWARE SETUP Section 3 14 ...

Page 58: ...MAKING A SAMPLE Section 5 4 ...

Page 59: ...Part 2 Laser System Essentials ...

Page 60: ......

Page 70: ...BASIC SYSTEM FEATURES Section 6 12 ...

Page 76: ...BASIC MAINTENANCE Section 7 6 ...

Page 77: ...Part 3 Accessories ...

Page 78: ......

Page 95: ...Part 4 Advanced User ...

Page 96: ......