20 UNIBLOC-PD Operation & Service Manual: PD600-677

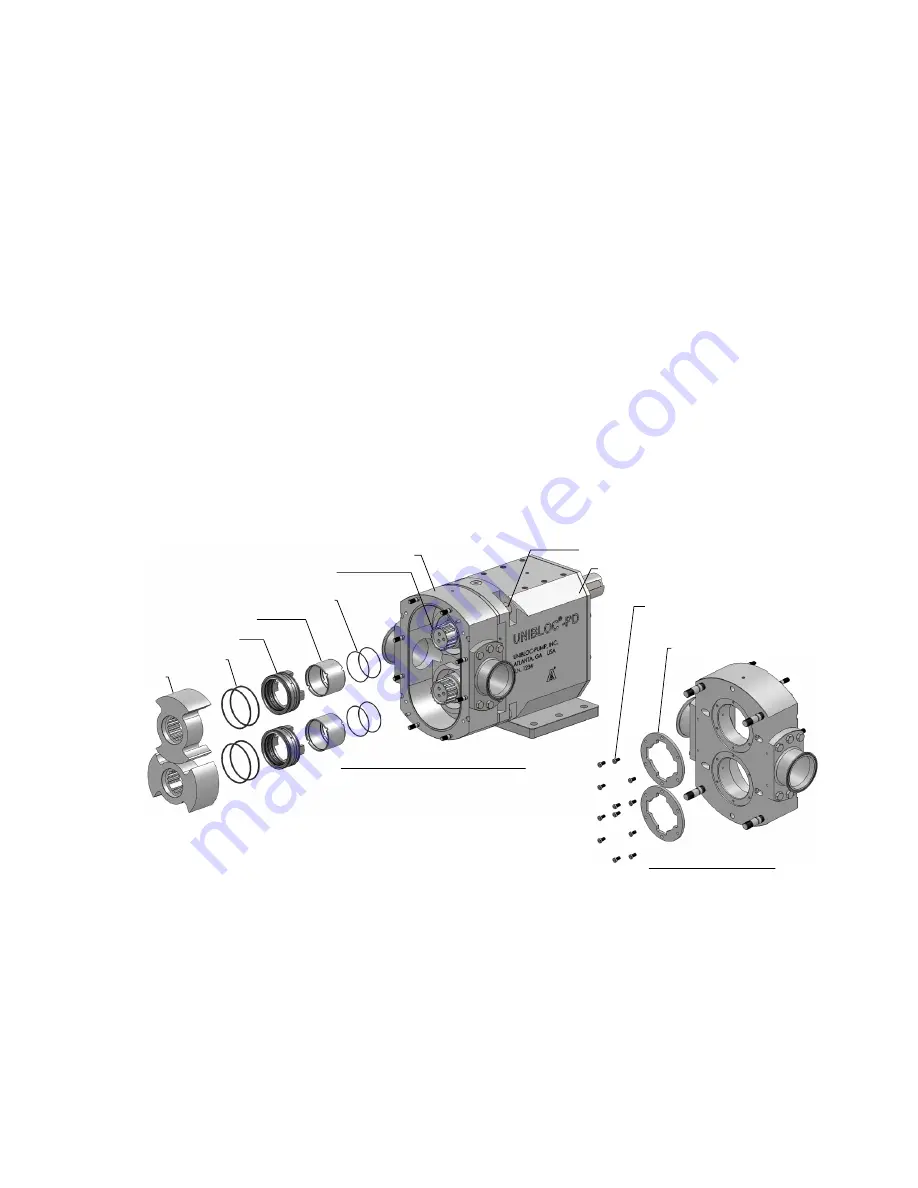

WEAR SLEEVE

SEAL CARTRIDGE O-RINGS

ROTORS

SEAL CARTRIDGE

WEAR SLEEVE O-RINGS

ROTOR HOUSING

SHAFTS

BEARING HOUSING

RETAINING RINGS

REAR VEW- ROTOR HOUSING

FRONT VEW- ROTOR & BEARING HOUSING

REAR ROTOR HOUSING STUD NUTS

RETAINING RING BOLTS

(6 or 8 Bolts Per Seal)

fig. 4.8

The

Rotating Seal Faces (primary)

must be pressed in evenly so that the

Rotating Seal Face O-rings

(primary)

do

not come off. They have been installed correctly if they do not fall out when tilting the rotors. Do not use objects that

will scratch the

Rotating Seal Faces’

surface to push them in. Place a product compatible lubricant on the sealing

surfaces of the

Stationary Seal Faces (primary)

and

Rotating Seal Faces (primary)

. Slide the

Rotors

on the

Shafts

. Proceed to section 4.4.6 to complete the installation.

4.4.4 Triple O-Lip

®

Seal- MODELS: PD600 to PD677

(reference figs. 4.1, 4.8)

This type of seal is most frequently used with liquids that are very difficult to seal because of high viscosity. The seal

comes as a single cartridge that is easily serviced. The maximum shaft rotational speed for this seal is 500 RPM and

the maximum service pressure should not exceed 10 bar (150 psig). The seal does not require external lubrication

and can be run dry for short periods. As an option, the seal can also be flushed providing an added barrier of protec

-

tion. Flushing systems may be arranged as shown in figures 3.4-3.6. The seal can be serviced without removing the

rotor housing.

4.4.4.1 Triple O-Lip

®

Seal Removal

(reference figs. 4.1, 4.8)

Slide the

Rotors

off the

Shafts

. If the rotors will not slide off they can be removed simultaneously with the

Rotor

Housing

. Unless they are being replaced,

DO NOT USE PLIERS OR CHANNEL LOCKS TO REMOVE THE RO-

TORS. THEY WILL BE DAMAGED.

Push the

Seal Cartridges

out of the

Rotor Housing

bores. Remove the

Seal

Cartridge O-rings

. Slide off the

Wear Sleeves

. If servicing the

Bearing Housing

, remove the

Rotor Housing

by

first disconnecting the flushing system, if applicable, and loosening the

Rear Rotor Housing Stud Nuts

. Use a hoist

and eye bolt to support the

Rotor Housing

. Tap on the ports with a rubber mallet and pull the

Rotor Housing

off. The

Retainer Rings

do not have to be removed to service the seal.

4.4.4.2 Triple O-Lip

®

Seal Installation

(reference figs. 4.1, 4.8, 4.15)

Clean all components prior to installing the seals. If the

Rotor Housing

was removed, assemble it to the

Bearing

Housing

first. Make sure

Retainer Rings

are attached to the

Rotor Housing

. Using an eye bolt, hoist the rotor

housing on the

Dowel Pins

(see fig. 4.15 on pg. 24) and slide it on, while at the same time threading on the

Rear

Rotor Housing Stud Nuts

. Tap the

Rotor Housing

with a rubber mallet to seat it properly against the

Bearing Hous-

ing

. Tighten the

Rear Rotor Housing Stud Nuts

in a cross pattern. Check the

Wear Sleeves

for excessive wear. If

grooves are noticeable, the sleeves may have to be replaced, otherwise the seal may not function properly or may fail

prematurely. Coat all

O-rings

,

Shafts

, and the seal surface of the

Wear Sleeves

with a lubricant that is acceptable for

contact with the product. Slide the

Wear Sleeves

on the

Shafts

and locate on the

Anti-Rotation Pins

. Slide mounting