UNIBLOC-PD Operation & Service Manual: PD600-677 17

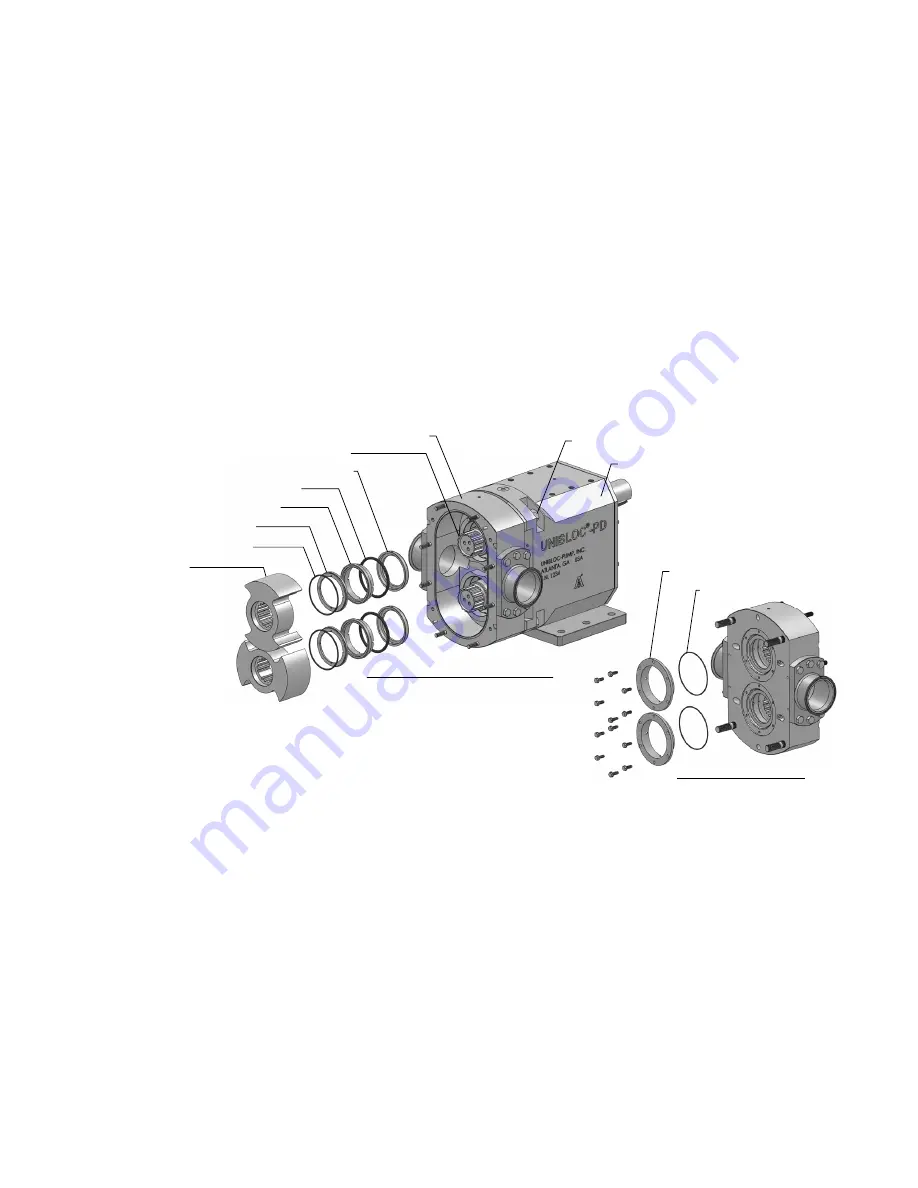

ROTATING SEAL FACES

ROTORS & PINS

ROTATING SEAL O-RINGS

STATIONARY SEAL FACES

ROTOR HOUSING

SHAFTS

BEARING HOUSING

STATIONARY SEAL O-RINGS

STATIONARY SEAL FACE HOLDERS

RETAINING RINGS

RETAINING RING O-RINGS

REAR VEW- ROTOR HOUSING

FRONT VEW- ROTOR & BEARING HOUSING

REAR ROTOR HOUSING STUD NUTS

fig. 4.5

4.4.2 Single Mechanical Seal

This type of shaft seal is used in most applications with products that have a viscosity of less than 14,000 cPs. The

maximum rotational speed of this seal is 600 rpm and the maximum service pressure is 20.7 bar (300 psig). The seal

materials available are stainless steel, carbon, and silicone carbide. The standard o-rings supplied in these seals are

Viton or EPDM, either food or FDA grade, but may be replaced with other materials as applications dictate. The seal

can be serviced without removing the rotor housing.

4.4.2.1.1 Single Mechanical Seal Removal- MODELS: PD600, PD650, PD675

(reference figs. 4.1, 4.5)

Slide the stainless steel

Rotors

off the shafts. If the rotors will not slide off they can be removed simultaneously with

the

Rotor Housing

. Unless they are being replaced,

DO NOT USE PLIERS OR CHANNEL LOCKS TO REMOVE

THE ROTORS. THEY WILL BE DAMAGED.

The

Rotating Seal Faces

,

Pins

, and

Rotating Seal O-rings

are

assembled inside the

Rotors

and will slide out with them. Slide the

Stationary Seal Face

,

Stationary Seal O-rings

,

and

Stationary Seal Holders

out of the housing. To avoid damage, handle and store the loose

Rotating Seal Faces

and the

Stationary Seal Faces

so that their lapped sealing surfaces do not get scratched. If servicing the

Bearing

Housing

, remove the

Rotor Housing

by first loosening the

Rear Rotor Housing Stud Nuts

. Use a hoist and eye bolt

to support the

Rotor Housing

. Tap on the ports with a rubber mallet and pull the

Rotor Housing

off. Unless being

serviced, the

Retaining Rings

may remain attached to the

Rotor Housing

.

4.4.2.1.2 Single Mechanical Seal Installation- MODELS: PD600, PD650, PD675

(reference figs. 4.1, 4.5, 4.15)

Clean all components prior to installing the seals. If the

Rotor Housing

was removed, attach it to the

Bearing

Housing

first. Make sure

Retaining Rings

with

Retaining Ring O-rings

are attached to the

Rotor Housing

. Using

an eye bolt, hoist the rotor housing on the

Dowel Pins

(see fig. 4.15 on pg. 24) and slide it on, while at the same time

threading on the

Rear Rotor Housing Stud Nuts

. Tap the

Rotor Housing

with a rubber mallet to seat it properly

against the Bearing Housing. Tighten the

Rear Rotor Housing Stud Nuts

in a cross pattern. Place the

Stationary

Seal Face Holders

against the

Stationary Seal Faces

so that the pins slide into the slots. Moisten the

Stationary

Seal O-rings

with water or coat them with a lubricant that is acceptable for contact with the product. Slide these

components in the rotor housing bores. If removed from the rotors, lubricate

Rotating Seal O-rings

and slide them

in the rotors together with the

Rotating Seal Faces

locating them on the seal pocket

Pins

on the back side of the

the

Rotors

. The

Rotating Seal Faces

must be pressed in evenly so that the

Rotating Seal O-rings

do not come off.

They have been installed correctly if they do not fall out when tilting the rotors. Do not use objects that will scratch

the

Rotating Seal Faces’

surface to push them in. Place a product compatible lubricant on the sealing surfaces of

the

Stationary Seal Faces

and

Rotating Seal Faces

. Slide the

Rotors

on the

Shafts

. Proceed to section 4.4.6 to

complete the installation.