Operating Manual

TYTAN premium

- p. 23 -

8.

Dismantling

and

withdrawal

from

use

1. The machine should be dismantled by at least 2 persons. Before starting the work they should read

and understand the Operating Manual.

2. The dismantling post should be equipped with a lifting device (overhead crane, crane or a hoist with

lifting capacity of 500 kg).

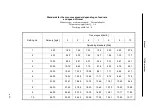

3. Disassembling steps:

- disassemble the rear lights bar, item 1

- disassemble the rear cover of the spreading adapter and remove the adapter, item 2

- disassemble the side swages with a front wall, item 3

- disassemble the rear damper with hydraulic cylinders, item 4

- disassemble the chain conveyor and the drive shaft with a site transmission box, item 5

- disassemble the PTO, item 6

- disassemble the side mudguards, item 7

- lift the chassis and disassemble the wheelset, item 8

- disassemble the drawbar and the drawbar support, item 9

- disassemble the pneumatic installation with the air tank, item 10

- disassemble the hydraulic installation hoses, item 11

- transport the frame to the storage spot

- discharge oil from the transmission box into a separate container

Worn-off parts of the power transmission system can be regenerated in specialist facilities. It is

permissible to weld small cracks in the frame and sides. Surfaces after welding must be cleaned and

protected from corrosion. Parts that are excessively worn-off or damaged must be withdrawn from

use, and after segregation they must be delivered to the waste disposal center.

While carrying out the actions mentioned above use proper tools, related to the kind of undertaken

disassembling activity. Be careful and observe the OHS regulations.