Operating Manual

TYTAN premium

- page 20 -

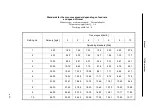

6.5. Faults in the machinery operation and their removal

Type of fault

Cause of fault

Manners of removal

The overload system (latch-

up) for discs is activated too

often during operation of the

spreader.

Overload

of

the

drive

mechanisms for the adapter

of floor conveyor. The clutch

is adjusted improperly (the

torque is too small).

Remove

the

cause

of

overload (foreign body or

clogging of the

spreader

’

s drums with compact

material.

Adjust

the clutch in accordance with

the guidelines in point 6.4.4.

The service brake system

does not work.

No pressure in the trailer’s air

tank. Friction linings of brake

shoes are worn off.

Check condition of brakes

and air pressure in the

pneumatic system. Check for

correctness of the coupling

between

the

pneumatic

system of the trailer with the

pneumatic system of the

tractor. Replace the worn off

friction linings of brake shoes

with new ones.

The trailer’s wheels brake

unevenly.

Friction linings of a brake

shoe in a single wheel are

worn off. The brakes are

adjusted improperly.

Replace the worn off lining of

a brake shoe.

Adjust

the

breaks in accordance with

guidelines in point 6.4.6.

Tires of trailer’s wheels wear

off unevenly.

Improper air pressure in the

tires.

The

trailer

is

overloaded.

Check

pressure

in

the

wheels’ tires and keep it at a

rated level. Do not exceed the

permitted loading capacity of

the trailer.

The conveyor hits the floor

and the load-

carrying box’s

frame,

the conveyor’s strikes

fall off

The conveyor chains are too

long.

Improper adjustment of

the conveyor chains tension.

Check for tension of the

chains and adjust it according

to the guidelines in point

6.4.3. When the full scope of

adjustment is utilized, shorten

all chains by removing the

same

number

of

links.

Straighten

the

conveyor

strikes.

The spreading adapter is

blocked (the machine is

clogged).

The feeding speed of the floor

conveyor is too high. The

clutch is adjusted improperly.

Decrease the feeding speed

of the conveyor and change

the movement direction.