Operating Manual

TYTAN premium

- page 17 -

Dose of the spread manure depends on:

- feeding speed of the floor conveyor, resulting from the hydraulic oil flow rate through the

flow adjuster.

- spr

eader’s speed of travel on the field;

- volume weight of the applied fertilizer;

- working width;

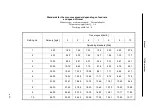

Indicative values of fertilization in tones per one hectare (t/ha) are provided in the table on pages

23 - 26.

NOTE:

While spreading the manure, the load-

carrying box’s damper must be lifted maximally with

hydraulic cylinders. Partial opening of the damper can cause certain resistance during

transportation of manure towards the adapter, causing damage to the conveyor, pushing the

damper out of the guides or damaging the hydraulic cylinders lifting the damper. The damper can

be opened partially while spreading loose materials; the minimum gap should be 400 mm.

While spreading manure, peat or compost use only lower

floor conveyor feeding speeds, in the range between 1 to 10 on the flow adjuster scale. If you

want to increase the dose of spread material, lower the working speed.

Higher speeds (10-12) serve for automatic unloading of the trailer. In order to get

the best spreading parameters (widths and un

iformity) rotations on the tractor’s PTO should be

kept at the level of 520 - 550 rpm.

Lower rpm in the spreading procedure causes a significant drop in the machine’s working

parameters.

The ladder fixed at the load-

carrying box’s side enables access to the interior in order to control

the filling level or carry out operational and repair activities.

6.4.3. Adjustment of the conveyor chains tension.

While utilizing the spreader, and first of all in the initial period, you must pay special attention

to maintenance of a proper tension of the conveyor chains. Backlash of the chains visible while

raising them perpendicularly to the direction of movement, at the half length of the load-carrying

box, should be as low as possible. Adjustment is realized via stretchers

located in the machine’s

front part.

Fig. 11

Mechanism for tensioning chains of the floor conveyor.

If the work range of the stretcher does not allow further tensioning of the chain, you need to remove

a proper number of the chain links. You shorten the chain by cutting off at least two chain links,

multiplying the number in case there is a need to shorten the chain more. Always remove the same

number of links from all chains.