Operating Manual

TYTAN premium

- p. 22 -

7. Maintenance and lubrication.

Lubrication of the spreader must be carried out in accordance with Fig. 14 of the lubrication table.

Lubricators heads must be carefully cleaned from mechanical contamination before using grease.

There are sight-glasses installed on mechanical gearboxes, serving for control of the oil level. In

case of deficiency pour oil to reach half of the sight-glass.

You should exchange oil in gearboxes directly after completion of the spreader operation. Having

discharged the oil, tighten the plug and pour new oil via the upper hole, to the level of a notch.

The gear boxes use GL-4 80W/90 gear oil.

Once a year, having removed the h

ub’s cover, fill in the grease in bearings. The assembled and

preserved spreader must be kept in a place protected from harmful influence of rain.

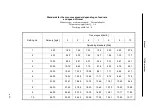

Lubrication points table

No. of the

lubrication

point

according

to Fig. 14

Lubrication point

No. of

lubrication

points

Grease

type

Lubrication frequency

I.

Housings of the

main drive

bearings.

Transmission boxes of

the vertical adapter

drive.

Upper housings of the

vertical rollers

bearings

3

4

4

ŁT 43

Always before

commencement of work

Later every 10 hours

II.

Bearings of the

conveyor drive shaft

Wheels tensioning the

conveyor

2

4

ŁT 43

Always before

commencement of work.

During work, not later than

after 100 hours.

III.

Hydraulic cylinders

bearings.

Support of the drawbar.

Pin of the drawbar. Pins

of the spring

suspension.

Brake expanders.

8

1.

2

6

2

STP

or ŁT

43

Every quarter. Lubricate

before longer standstill and

storage for winter.

The vertical adapter

transmission set

1

GL

– 4

Every season

Conveyor transmission box 1

GL

– 4

Every season