Operating Manual

TYTAN premium

- page 15 -

6.3. Loading and unloading the trailer.

The trailer should be loaded with a crane, loader or conveyor. The load should be

distributed evenly throughout the whole surface of the load-carrying box floor. Loading of the

manure (peat or compost) should be realized from the rear to the front side of the trailer, what

exerts positive influence on quality of later spreading. Loading of other materials with utilization of

the trailer as a transportation mean, should take place in a reverse order, i.e. from the front to the

rear side of the trailer. While transporting loads that exert significant point pressure on the load-

carrying box floor, what should be avoided, you need to lay thick planks on the surface, providing

surface load, and protecting from damaging the floor and chain conveyor.

6.4. Principles of correct use of the machinery.

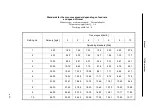

6.4.1. Adjustment of the manure dose.

During the fertilization process, the machine’s floor conveyor feeds in direction that is

opposite to the direction of travel, from the tractor to the spreading adapter. The conveyor can

feed in the other direction only in special circumstances, i.e. the machine is clogged or there is a

procedure of cleaning the spreading rollers from foreign elements, but not more than 30 cm.

The conveyor feeding direction depends on the hydraulic oil flow direction through the system,

and the feed rate is adjusted in a stepless manner, with a flow rate hand wheel.

There should be no pressure in sockets and plugs of the push-in fittings during

the coupling process. The coupling must be strong and reliable.

When the work is done, disconnect the cables in a reverse order.

6.4.2. Spreading adapter

Safety and reliability of the adapter’s operation depends to a significant extent on foreign

bodies located in the manure (e.g. stones, wood, etc.). Furthermore, strings present in the manure

can wrap the spreading rollers, causing a drop in the adapter efficiency. The entangled strings

must be immediately removed, otherwise a failure can occur. The wrapped string must be removed

with a sharp tool.

The adapter should be installed on the spreader’s frame with a crane. For this purpose, connect

hooks of the sling with the adapter’s catches located in its upper part.

If the spreading adapter is blocked, you

must

turn the hydraulic drive of the

floor conveyor off.

Bearing in mind significant oil pressure, which is necessary for proper operation

of the machine, the tractor must have a working system of external hydraulics

and a proper oil level.

A4VS and A2VS vertical adapters

The spreader can be equipped with two kinds of horizontal adapters, four-roller A4VS and two-

roller A2VS. The four-roller vertical adapter has spreading drums, inclined at a level of 15°. Two

internal drums have smaller diameter than the external drums, what causes lower rotational

speed of cutting knives located at the circumference, and this better break-up of the manure. The

two-roller vertical adapter has two spreading drums with a large diameter, inclined at the level of

15°.

Bigger diameter causes bigger working width. Worn-off knives can be replaced with new