27

5.1

Installation

5.1.2.2 Installation

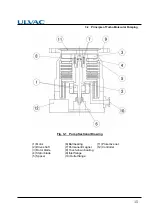

Refer to Fig. 5-3 for the method to fix the turbo molecular pump to host equipment.

When you fix the pump, use the bolts regulated grade, size, number and tightening torque

(Refer to Table 5-1 and Table 5-2). And use all the bolt-holes of the inlet flange of the pump.

Refer to Fig. 5-4 about usage of the bolt.

The sets of half-screw bolt and nut should be used to fix the inlet flange of the pump. Make

installation with the cylindrical part of the bolt (not screw part) fit in the mating section of flanges.

When you connect piping or valve between the chamber and the pump, please fix the same

method as the inlet flange.

Description

Rapid shutdown torque (Note)

UTM300B

5400 N

・

m

(Note) Rapid shutdown torque is the typical value measured by the ULVAC’s test condition.

The torque to transmit to host equipment might be different according to the rigidity of

host equipment. Host equipment should be designed to have enough margins in strength.

Fig. 5-3

Installation of Turbo Molecular Pump

Summary of Contents for UTM300B

Page 8: ...vii Location of label...

Page 11: ...x This page is intentionally left blank...

Page 17: ...xvi Table of contents This page is intentionally left blank...

Page 51: ...34 SECTION 5 INSTALLATION This page is intentionally left blank...

Page 70: ...GAS PURGE 7...

Page 77: ...60 SECTION 8 TURBO MOLECULAR PUMP RECONDITION This page is intentionally left blank...

Page 111: ...A 26 Appendix A COMMUNICATIONS This page is intentionally left blank...