SECTION 3

7

NOTE

If the hearth is to be driven with motor, the revolution of the hearth drive

shaft should be set at below 5 rpm.

(14)

Electric current feed-through for hearth position detection

*

ULVAC Model PTS-004 (8P) can be used.

However, this feed-through is not required if the hearth drive shaft is turned

by hand and a mechanism for detecting the crucible position mechanically is

provided.

(15)

Cooling water equipment

The Model EGL-206M/EGL-406M requires a water flow rate of 10 L/min or

more. Water pressure requirement is 3 to 3.5 kg/cm

2

or more, which slightly

varies with piping arrangement and length.

If water flow rate is not enough, pressurization by installing a pressor pump

near the deposition equipment is needed.

WARNING

1.

For thin piping subject to back-pressure or pressure loss, extra pressure

should be taken into account.

2.

It is recommended to use water whose specific resistance is 5 k cm or

more (dissolved solid components 100 ppm or less). Water with a

specific resistance of less than 5 k cm can also be used, but the water

path in the hearth will be contaminated over a long time of operation,

resulting in insufficient cooling, which may shorten the service life of the

hearth.

Summary of Contents for EGL-206M

Page 2: ...EB0007 03e...

Page 3: ...EB0007 03e...

Page 10: ......

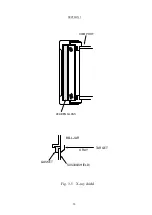

Page 13: ...SECTION 1 3 Fig 1 1 Dimensional Drawing for EGL 206M EGL 406M...

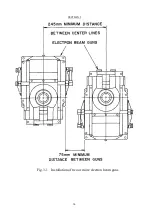

Page 24: ...SECTION 3 14 Fig 3 1 Installation of two or more electron beam guns...

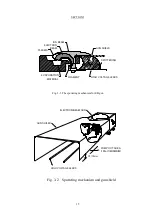

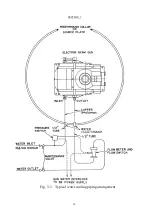

Page 26: ...SECTION 3 16 Fig 3 3 Typical water cooling piping arrangement...

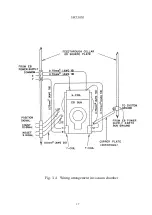

Page 27: ...SECTION 3 17 Fig 3 4 Wiring arrangement in vacuum chamber...

Page 38: ...SECTION 5 28 Fig 5 1 Exploded view of emitter assembly and dimensional drawing for electrode...

Page 42: ...SECTION 5 32 Fig 5 2 Exploded view of EGL 206M EGL 406M...