SECTION 1

1

1. GENERAL

The electron beam evaporation source EGL-206M/EGL-406M provides higher

performance and reliability based on ULVAC's years of accumulation of

technologies and actual achievement. EGL-206M/EGL-406M has six crucibles

with a capacity of 20cm

3

(a maximum power supply of 8kW) and EGN-406M

has six crucibles with a capacity of 40cm

3

(a maximum power supply of 8kW),

both of which provide flexible multilayer film vapor deposition.

The general features of electron beam vapor deposition are as follows.

This can input high density energy into a micro area, which enables

evaporation of high melting point metal, such as W, Ta, and Mo, and

oxides, such as SiO

2

and Al

2

O

3

.

With a water-cooled copper crucible, the pollution from the contact part

with evaporation materials is very low and high-purity vapor-deposited

film can be obtained.

A normal heat resistance evaporation source needs frequent

replacement of the filament, the boat, etc. depending on the evaporation

material, whereas an electron beam evaporation source is essentially

low in wear of the component parts.

1.1

Features of EGL-206M/EGL-406M

(1)

A 6-point switching hearth with a capacity of 20cm

3

/ 40cm

3

is adopted,

providing vapor deposition of multilayer film.

(2)

An electron beam deflects depending on the electromagnetic field, which

has an extremely low effect of secondary electrons on the object subject

to vapor deposition.

(3)

Even sublimation substances can be smoothly evaporated by scanning the

beam spot on the X-axis and the Y-axis to eliminate a "hole-digging"

phenomenon.

(4)

The electron beam is of 270

゚

deflection and therefore not subject to

evaporation, making the filament lifetime longer.

(5)

The easy-to-detach emitter assembly provides easy replacement of the

filaments, isolation insulators, etc.

(6)

The mounted hearth position detecting function enables automation of

the hearth rotation.

Summary of Contents for EGL-206M

Page 2: ...EB0007 03e...

Page 3: ...EB0007 03e...

Page 10: ......

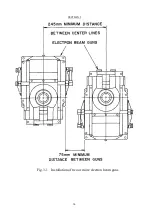

Page 13: ...SECTION 1 3 Fig 1 1 Dimensional Drawing for EGL 206M EGL 406M...

Page 24: ...SECTION 3 14 Fig 3 1 Installation of two or more electron beam guns...

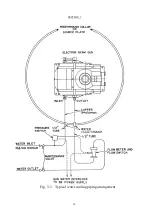

Page 26: ...SECTION 3 16 Fig 3 3 Typical water cooling piping arrangement...

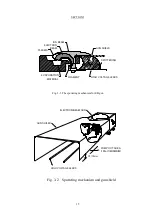

Page 27: ...SECTION 3 17 Fig 3 4 Wiring arrangement in vacuum chamber...

Page 38: ...SECTION 5 28 Fig 5 1 Exploded view of emitter assembly and dimensional drawing for electrode...

Page 42: ...SECTION 5 32 Fig 5 2 Exploded view of EGL 206M EGL 406M...