UBI EasyCoder 501 – Service Manual

43

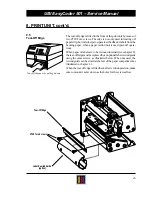

8.3

Pressing Roller

8. PRINT UNIT, cont'd.

The pressing roller is coated with silicon rubber. It is imperative that

the roller is clean, free from uneven wear or dents, and exactly

aligned with the printhead (see chapter 24.3). The roller is sup-

ported by two ball bearings and can be replaced as follows:

• Remove the screws that hold the stepper motor to the motor

bracket and pull out the motor. Do not remove the bracket.

• Pull the belt away from the pulley of the pressing roller.

• Using a 2 mm hexagon wrench, loosen the single grub screw that

hold the pulley on the shaft.

• Using a #T20 Torx screwdriver, remove the bracket that holds the

bearing at the outer end of the shaft.

• Pull out the roller and the two ball bearings.

• Reassemble in reverse order using a fresh set of roller and ball

bearings. The distance between the pulley of the pressing roller

and the inner gable of the print unit should be 5 mm (.2").

• Check the tension of the belt (see chapter 8.4). Also check printout

quality by means of test labels (see chapter 24.1).

Upper part of print unit

omitted to give better view.

Belt

Ball Bearing

Ball Bearing

Stepper

Motor

Bracket

Pulley

Pressing Roller

Bracket

#T20 Torx Screw

NOTE!

Stepper motor bracket dismantled to

give better view. Bracket does not need

to be dismantled for replacing the

pressing roller.