40

EMP

Installation & Service Manual

109529-03 - 11/19

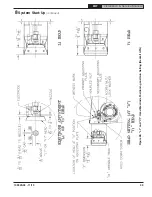

Figure 29: Electrode Tip Gap and Spacing

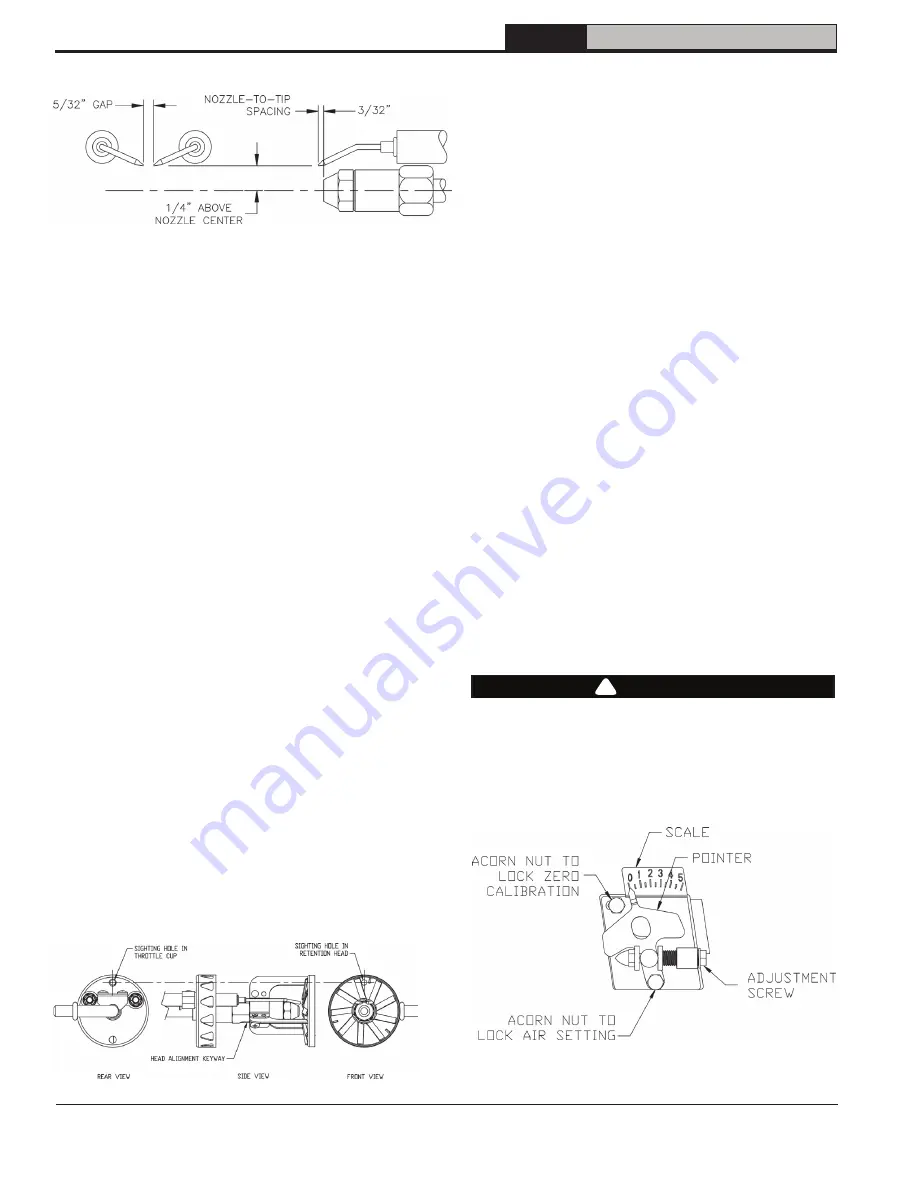

Figure 30: Retention Head/Throttle Cup Alignment

Figure 31: Head/Air Adjustment Plate Assembly

c. Disconnect the copper oil connector tube

from nozzle line.

d. Loosen the two screws securing igniter-

retaining clips and rotate both clips to

release the igniter baseplate. The igniter

should pop-up and would be supported by

the prop spring.

e. Loosen the two screws securing the rear

door, then swing to the right and down.

f. Loosen splined nut.

g. Lift up the igniter baseplate and

simultaneously remove nozzle line assembly

from burner by drawing it straight back out

the rear door opening. Be careful not to

damage the electrodes or insulators while

handling.

h. Check electrodes to comply with

dimensions shown in Figure 29. For

adjustment, loosen the electrode clamp

screw and slide /rotate electrodes as

needed. Securely re-tighten the clamp

screw when finished.

i. Check retention head alignment. Cad

cell sighting holes in the throttle cup and

retention head must line up, so the cad

cell can see the flame. Make sure that the

"stamped key" in the retention head collar

lines up with the "keyway" in the nozzle

adapter, when mounting the retention head.

See Figure 30.

j. To re-install the nozzle line assembly,

reverse procedure outlines in steps f thru b.

k. Upon reinstallation of the nozzle line

assembly, check that head/air plate setting

number pointer line up with a number on

the scale,

which matches a value shown in Table 10 for

a particular boiler/burner model.

The zero calibration has been factory set;

the upper left acorn nut locks retention head

at “0” position. If the zero calibration has to

be reset, follow the adjustment procedure,

outlined at “Prepare Burner & Site” section

of Beckett Model NX Oil Burner Instruction

Manual, Form Number 610BNX. Make

sure the retention head is securely against

the stops in the retention ring, when the

adjustment plate pointer is at “0”.

l. The rear door must be kept tightly closed

upon reinstallation of the nozzle line

assembly.

m. Loosening the splined nut and lower acorn

nut, and, turning the adjustment screw,

either forward or, rearwards, will adjust the

head/air plate. DO NOT LOOSEN UPPER

LEFT ACORN NUT, which locks zero head/

air setting. See Figure 31.

n. OPEN ALL SHUT-OFF VALVES in the oil

supply line to the burner.

o. ATTACH A PLASTIC HOSE TO FUEL PUMP

VENT/BLEED FITTING and place the other

hose end into an empty container to catch

the oil.

p. SLIGHTLY OPEN FLAME OBSERVATION

PORT COVER on burner swing door,

enough to insert draft gauge probe later.

WARNING

Very hot flue gases come out of flame

observation port cover hole when boiler is

operated with port cover open. Always wear

proper eye protection.

8

System Start-Up

(continued)

!