29

EMP

Installation & Service Manual

109529-03 - 11/19

3. Pull outer vent pipe back 1” to 2” from end of

inner vent pipe and remove insulation; firstly,

at vent pipe end to be connected to the vent

termination; secondly, at vent pipe end to

be connected to the appliance adapter. See

Figure 19.

4. Install supplied Cover Sleeve Assembly onto

each end of outer vent pipe, and, move the

assembly a few inches back from the end;

firstly, at vent pipe side to be connected to the

vent termination; secondly, at vent pipe side

to be connected to the appliance (boiler outlet

collar) adapter. See Figure 19.

5. Slide supplied Cover Rings; firstly, over stop

bead on vent termination inner pipe; secondly,

over stop bead on appliance adapter. See

Figure 19.

6. Remove any oil and grease from the end of

vent termination inner pipe, and, from the end

of the appliance adapter.

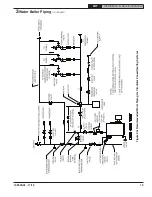

7. Apply sealant; firstly, between the stop bead

and retainer bead at the end of the vent

termination inner pipe; secondly, between the

stop bead and retainer bead at the end of the

appliance adapter. See Figure 20.

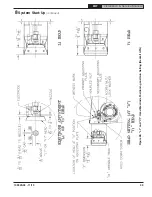

8. Assemble supplied inner pipe clamp halves

with 1/4-20 bolts and square nuts; position the

inner pipe clamps ¼” from the end of inner

vent pipe, on vent pipe opposite ends.

9. Remove any oil and grease from inside of each

end of the inner vent pipe.

10. Apply a thick bead of sealant to inside of each

end of the inner vent pipe, ½” from pipe end,

working the sealant into the inner vent pipe

corrugations. See Figure 20.

11. Firstly, push one end of the inner vent pipe onto

the vent termination inner pipe, all the way up

to the stop bead. Secondly, push the opposite

end of the inner vent pipe onto the appliance

adapter, all the way up to the stop bead.

12. Tighten the inner pipe clamp bolts at both vent

pipe ends, until clamp halves are within 1/8”

apart. See Figure 21.

13. Starting with vent termination end, slide the

cover sleeve assembly and the cover ring

together to engage the ring in the groove of the

sleeve, then, tighten the built-in cover sleeve

clamp. Repeat above steps at the boiler end.

See Figure 21.

14. If the appliance collar is within less than 18"

of combustible material, wrap minimum 1-1/2"

thick fiberglass insulation (installer provided).

15. To maintain vent pipe 1" clearance to

combustible material, wrap minimum 1-1/2"

thick fiberglass insulation (installer provided)

around the exposed portion of the vent

termination inner pipe and secure with

adhesive-backed aluminum foil tape (installer

provided).

Figure 20: Vent Pipe Ends, Vent Termination and Appliance Adapter Sealing

F . CONNECTING FLEX OIL VENT PIPE TO

APPLIANCE ADAPTER AND DIRECT VENT

TERMINATION

1. Flexible double wall oil vent pipe is available pre-

cut 10 ft and 20 ft long. If necessary, the vent pipe

may be cut to required length with a hacksaw or

cutoff saw.

CAUTION

Use safety glasses and other appropriated

safety gear when cutting the vent pipe.

2. The double wall flexible vent pipe consists of the

smaller inner corrugated stainless steel pipe and

larger corrugated aluminum pipe, separated by

fiberglass insulation layer.

CAUTION

The inner and outer pipe ends may have sharp

burrs. Use gloves, while handling, compressing

or expanding the vent pipe.

5

Direct Venting / Air Intake Piping

(continued)

!

!