– 161 –

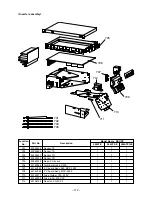

Pipe cover, bundling band,

each sensor (TL, TO, TE, TS sensor)

PMV coil lead

Suction pipe

Pipe cover, bundling band, TS sensor

Compressor lead

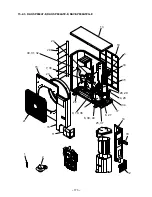

Pass the soundproof plate (outer winding)

Pass the soundproof plate (outer winding)

through between the suction pipe and

through between the suction pipe and

the accumulator.

the accumulator.

Do not make clearance between

the soundproof plate (upper) and

the soundproof plate (outer winding).

Put the soundproof plate

(outer winding) on the

other side at this position.

Soundproof plate

Soundproof plate

(upper)

(upper)

Soundproof plate

Soundproof plate

(outer winding)

(outer winding)

Soundproof plate

(upper)

Soundproof plate

(outer winding)

Accumulator

Accumulator

Header pipe

Header pipe

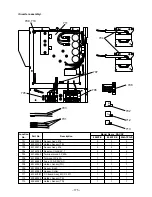

0 to 50

0 to 50

(Positioning

(Positioning

standard of

standard of

compressor

compressor

lead wire)

lead wire)

Ferrite core

Ferrite core

Using the bundling band on the market,

fix the bundle at 2 positions.

Wind the ferrite core

Wind the ferrite core

with the compressor

with the compressor

lead wire by 4 times.

lead wire by 4 times.

0 to 50

(Positioning

standard of

compressor

lead wire)

Ferrite core

Wind the ferrite core

with the compressor

lead wire by 4 times.

Suction pipe

Suction pipe

Pass the soundproof plate (outer winding)

through between the suction pipe and

the accumulator.

Pass the soundproof plate

Pass the soundproof plate

(inner winding) through

(inner winding) through

between compressor and

between compressor and

discharge pipe, suction pipe

discharge pipe, suction pipe

and then put it on the other

and then put it on the other

side at this position.

side at this position.

Accumulator

Discharge pipe

Discharge pipe

Discharge pipe

Header pipe

Suction pipe

Discharge pipe

Discharge pipe

Discharge pipe

Black heat-proof pipe cover and

heat-proof bundling band,

each sensor (TL, TO, TE, TD, TS sensor)

PMV coil lead wire

Set each sensor so that it does not

come to contact with the discharge pipe.

PMV coil lead

Pass the soundproof plate

(inner winding) through

between compressor and

discharge pipe, suction pipe

and then put it on the other

side at this position.

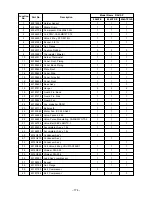

No.

6

Part name

Compressor

Compressor lead

(Continued)

Procedure

2. Mounting of compressor

1) Mount the compressor in the reverse

procedure of removal.

NOTES:

∗

After exchange of the compressor, be sure to

exchange the compressor lead. (Repair part

code of compressor lead: 43160591)

In this time, wrap the ferrite core with the

compressor lead wire by 4 times.

Using bundling band on the market, bind the

compressor lead. As the compressor lead is

long, be sure that the compressor lead does

not contact with the discharge pipe.

∗

Fix the removed each sensor and PMV coil

lead wire to the discharge pipe and the

suction pipe with the bundling band via the

pipe cover.

In this time, take note that each sensor and

PMV coil lead wire do not come to contact

with the discharge pipe and the reactor.

(For fixing to the discharge pipe, use the

black heat-proof pipe cover and the bundling

band for heat-proof which is sold on the

market.)

∗

As shown in the right figure, mount the

soundproof plate (inner winding, outer

winding) by inserting between the compres-

sor and the piping, and between piping and

the partition plate.

∗

Put the compressor lead wire and the

compressor case thermo between inner

winding and outer winding of the soundproof

as if dropping them in.

Remarks