– 61 –

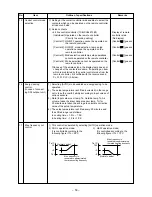

Abnormal stop

Frequency normal down

Frequency slow down

Frequency hold

Frequency slow up (Up to command)

As command is

HEAT TC / COOL TL

[˚C]

e

d

c

b

a

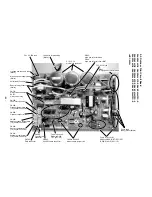

7. Current release value shift control

1) This control purposes to prevent troubles of

the electronic parts such as the compressor

driving elements and the compressor during

cooling operation.

2) The current release control value (

1

1) is

selected from the following table according to

TO sensor value.

Current release control value (

1

1)

[A]

Temperature range

50°C

≤

TO

45°C

≤

TO < 50°C

39°C

≤

TO < 45°C

TO < 39°C

TO error

SP56

SP80

7.80

9.5

7.80

9.5

9.30

13.0

10.80

16.0

7.80

9.5

8. Over-current protective control

1) When the over-current protective circuit detected an abnormal current, stop the compressor.

2) The compressor restarts after 2 minutes 30 seconds as setting [1] as an error count.

3) When the error count [8] was found, determine an error and restart operation is not performed.

4) For the error display contents, confirm on the check code list.

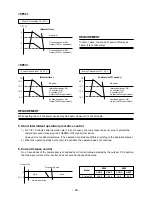

9. High-pressure release control <SP80 only>

1) The operation frequency is controlled to restrain abnormal rising of high pressure by TL sensor in

cooling operation and TC sensor in heating operation.

2) When TL sensor in cooling operation or TC sensor in heating operation detects abnormal temperature of

the stop zone, stop the compressor and the error count b1.

3) When the compressor stopped with 2), the operation restarts from the point of the normal operation

zone (e point or lower) where it returned after 2 minutes 30 seconds.

4) The error count when the compressor stopped with 2) is cleared after the operation continued for

10 minutes.

If the error count becomes [10] without clearing, the error is determined and reactivation is not performed.

5) For the error display contents, confirm on the check code list.

a

b

c

d

e

HEAT

COOL

TC

TL

61°C

63°C

56°C

62°C

54°C

60°C

52°C

58°C

48°C

54°C