– 116 –

12-1-6. Monitor Function of Remote Controller Switch

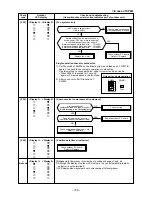

n

Calling of sensor temperature display

<Contents>

Each data of the remote controller, indoor unit and outdoor unit can be understood by calling the service

monitor mode from the remote controller.

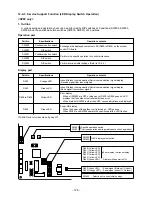

<Procedure>

1

Push

TEST

+

CL

buttons simultaneously for 4 seconds to

call the service monitor mode.

The service monitor goes on, the master indoor unit No. is

displayed at first and then the temperature of item code

is

displayed.

ò

2

Push temperature set

TEMP.

buttons and then change

the item code of data to be monitored.

The item code list is shown below.

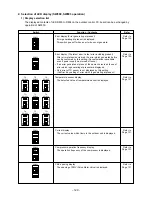

<Operation procedure>

1 2 3 4

Returned to usual display

2

4

1

3

SET

TIME

TIMER SET

TEST

FILTER

RESET

TEMP.

CL

FAN

SAVE

SWING/FIX

VENT

MODE

ON / OFF

UNIT LOUVER

ò

3

Push

UNIT LOUVER

button to select the indoor unit to be monitored.

Each data of the indoor unit and its outdoor units can be monitored.

ò

4

Pushing

TEST

button returns the status to the usual display.

∗

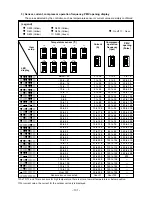

1 The indoor discharge temperature of item code [F8] is the estimated value from TC or TCJ sensor.

Use this value to check discharge temperature at test run.

(A discharge temperature sensor is not provided to this model.)

• The data value of each item is not the real time, but value delayed by a few seconds to ten-odd seconds.

• If the combined outdoor unit is one before 2 or 3 series, the outdoor unit data [6D], [70], [72] and [73]

are not displayed.

Indoor unit data

Item code

01

02

03

04

F3

Data name

Room temperature

(Remote controller)

Indoor suction temperature (TA)

Indoor heat exchanger (Coil)

temperature (TCJ)

Indoor heat exchanger (Coil)

temperature (TC)

Filter sign time

Unit

°C

°C

°C

°C

×1h

Outdoor unit data

Item code

60

61

62

63

65

6A

F1

Data name

Outdoor heat exchanger (Coil) temperature (TE)

Outside temperature (TO)

Compressor discharge temperature (TD)

Compressor suction temperature (TS)

Heat sink temperature (THS)

Operation current (× 1/10)

Compressor calculated operation time

Unit

°C

°C

°C

°C

°C

A

×100h