Item

Description of operation, numerical data, and other information

Remarks

12. Inverter

P.C.

board

control for

compressor

(1) Current, power release value control

The purpose of this control is to prevent high pressure rise and overheating of electric

parts by reducing the compressor speed when the maximum current and maximum

power value set for each model are exceeded.

The maximum current and power value for each horsepower

of each model are as follows

*2 For comp models, it is the maximum value per comp.

Even when the TH sensor temperature ≥ 81°C, the compressor speed is reduced, and

when the TH sensor temperature < 73°C continues, the rotation speed increase is

permitted.

(2) Heat sink overheat abnormality

Stop the compressor operation when the TH sensor temperature exceeds 93°C.

When the above is stopped, the abnormal count is set to 1, and it restarts after 2

minutes and 30 seconds.

If you continue the operation for 10 minutes or more after restarting, the trouble count

will be cleared

A trouble is confirmed with a trouble count of "4".

HP

24*

22*

20

18

16

14

12

10

8

Maximum current

27.00A

25.50A

36.00A

34.00A

30.50A

27.50A

24.50A

20.50A

15.40A

Maximum power

17.21kW

16.25kW

22.94kW

21.67kW

19.44kW

17.52kW

15.61kW

13.06kW

9.81kW

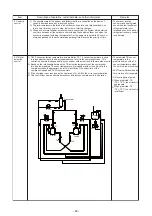

(3) High pressure SW control

Inverter compressor stops driving the compressor when the high pressure SW is

operating.

When the above is stopped, the abnormal count is set to 1, and it restarts after 2

minutes and 30 seconds.

If you continue the operation for 10 minutes or more after restarting, the trouble count

will be cleared.

The trouble count becomes "4" and the trouble is confirmed.

The above display is "P04".

1

4A

27

.

00

A

1

7

.

21

kW

- 54 -

Summary of Contents for MMY-MUP0801HT7JP

Page 309: ......