e-STUDIO202S OPERATIONAL DESCRIPTIONS 7 - 4

A. General description

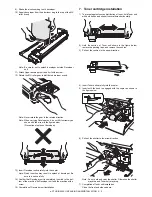

General block diagram (cross section)

Top view

(1) Heat roller

A Teflon roller is used for the heat roller and a silicone rubber roller

is used for the lower heat roller for better toner fusing performance

and paper separation.

(2) Separator pawl

Three separator pawls are used on the upper heat roller. The sep-

arator pawls are Teflon coated to reduce friction with the roller and

prevent a smear on the paper caused by the separator pawl.

(3) Thermal control

1) The heater lamp, thermistor, main PWB, DC power supply

PWB, and triac within the power supply unit are used to control

the temperature in the fuser unit.

To prevent against abnormally high temperature in the fuser

unit, a thermal breaker and thermal fuse are used for safety

purposes.

2) The surface temperature of the upper heat roller is set to 160 -

200°C. The surface temperature during the power save mode

is set to 100°C.

3) The self-check function comes active when one of the follow-

ing malfunctions occurs, and an "H" is displayed on the multi-

copy window.

a. When the heat roller surface temperature rises above 240°C.

b. When the heat roller surface temperature drops below 100°C

during the copy cycle.

c. Open thermistor

d. Open thermal fuse

e. When the heat roller temperature does not reach 190°C within

27 second after supplying the power.

(4) Fusing resistor

This model is provided with a fusing resistor in the fusing section

to improve transfer efficiency.

Since the upper heat roller is conductive, when using copy paper

that contains moisture and the distance between the transfer unit

and the fusing unit is short, the transfer current may find a path to

ground via the copy paper, the upper heat roller and the discharg-

ing brush.

5. Paper feed section and paper

transport section

A. Paper transport path and general operations

Paper feed is made in two ways; the tray paper feed and the man-

ual paper feed. The tray is of universal-type, and has the capacity

of 250 sheets.

The front loading system allows you to install or remove the tray

from the front cabinet.

The general descriptions on the tray paper feed and the manual

paper feed operation are given below.

Separator pawl

Separator pawl

PPD2

Thermal fuse

Thermistor

Heat roller

Paper guide

Pressure roller

Heat roller

Thermistor

Thermal fuse

Heater lamp

Separator pawl

Safety device

(thermal breaker, thermal

fuse)

Triac (in the

power supply unit)

Heated by the heater

lamp. (950W)

The surface temperature

of the upper heat roller is

sensed by the thermistor.

Level of the thermistor is

controlled by the main PWB.

With the signal from the

main PWB, the triac is

controlled on and off.

(power supply PWB)

1

Scanner unit

8

Drum

2

Copy lamp

9

Transfer unit

3

LSU (Laser unit)

10

Pickup roller

4

Paper exit roller

11

Manual paper feed tray

5

Main charger

12

Manual paper feed roller

6

Heat roller

13

PS roller unit

7

Pressure roller

14

Paper feed roller

1

5

4

3

7

6

8

9

11

12

13

14

10

2