23

6.5.3 Weekly Maintenance (40 Hours)

CAUTION:

Perform all electrical work with power secured.

1.

CABLE CONNECTIONS- Check all electrical lead connections from power supply to

wire feeder. The connections must fit firmly, a loose fit will cause the leads to heat up.

Use a screwdriver to spread the male prong for a tight fit.

2.

FEEDER CONNECTIONS- Check the fittings inside the feed unit, tighten all bolts that

connect the current to the wire feed assembly.

3.

POWER SUPPLY- Disconnect the power supply from the primary current. Remove the

side covers then remove the dust from inside the machine with an air hose.

6.5.4 Monthly Maintenance (160 Hours)

CAUTION:

Perform all electrical work with power secured.

1.

TIPS- Replace

2.

CONTACT TUBE HOLDER- Replace

3.

LINERS- Replace

4.

FEED ROLLS- Inspect the knurled surface for wear, replace if required

5.

FEED ROLL BEARINGS- Inspect feed roll bearings, these bearings will eventually wear

to a point of requiring replacement (usually more than 2000 hours of operation). If wear

causes misalignment of the gears and off center rotation, it is time for replacement.

6.

ELECTRICAL CONNECTIONS- Inspect power lead connections for oxidation,

disconnect all fittings, sand clean with sandpaper or file, then re-connect or replace if

necessary.

Summary of Contents for BRIDGEMASTER

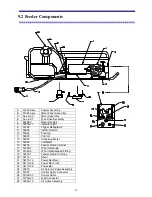

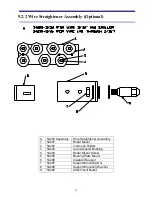

Page 20: ...7 3 System Assembly drawing shows optional straighteners...

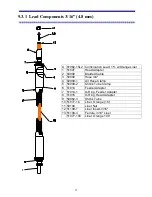

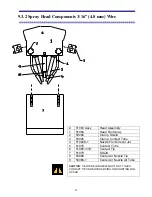

Page 30: ...17 6 2 1 Angle Spray Nozzle 3 16 4 8 mm Wire Head...

Page 31: ...18 6 3 Air Nozzle Alignment 1 8 3 2 mm Wire Head...

Page 32: ...19 6 3 2 Angle Spray Nozzle 1 8 3 2 mm Wire Head...

Page 57: ...44 9 4 1 System Wiring...