15

6.1 Operating Parameters

Operation:

Most materials will operate at a wide range of voltage and amperage settings,

excessive amperage may burn out chemical elements critical for the device

intended and provide poor deposit efficiency.

Wire Size:

The Bridgemaster can spray up to 3/16" diameter wire. 1/8" (3.2 mm) and 3/16"

(4.8 mm) diameter aluminum and zinc are the optimum size for the Thermion

equipment. 1/16" (1.6 mm) and 3/32" (2.4 mm) diameters are the most common

used sizes of the hard wire types.

Voltage:

Voltage controls arc gap. Normal range for low melting, soft materials is between

24 and 32 volts. Normal range for higher temperature hard wires is between 28

and 35 volts.

Amperage:

Amperage can be varied considerably for all materials. Non-alloyed materials, i.e.

aluminum, zinc, tin, etc. can be operated without fear of dealloying. However,

this equipment runs 3/32" (2.4 mm) material best at 200-250 amps and 1/8" (3.2

mm) and 3/16" (4.8 mm) between 250 and 500 amps. Alloyed material of 1/16”

(1.6 mm) and 3/32" (2.4 mm) size operates and maintains reasonable chemistry at

180-250 AMPS.

Adjusting Parameters:

Set the wire feeder volt dial on 80% & amp dial on 40%, start spraying at this

setting and while machine is running, adjust amperage to desired setting, then

lower voltage to minimum given in spray tables or until erratic arc is noticed.

Then, raise voltage until arc smoothes out.

Material

Size

Volts

Amps

Air Pressure

Aluminum

3 mm - 4.8 mm (1/8" - 3/16")

28-32

350-500

90-110 PSI

Zinc

3 mm - 4.8 mm (1/8" - 3/16")

28-32

325-500

90-110 PSI

Zinc-

Aluminum

3 mm - 4.8 mm (1/8" - 3/16")

28-32

300-500

90-110 PSI

Steels

1.6 mm - 2.4 mm (1/16” - 3/32")

28-35

200-250

90-110 PSI

Bronzes

1.6 mm - 2.4 mm (1/16” - 3/32")

28-35

200-250

90-110 PSI

400 Stainless

1.6 mm - 2.4 mm (1/16” - 3/32")

28-35

200-250

90-110 PSI

300 Stainless

1.6 mm - 2.4 mm (1/16” - 3/32")

28-35

200-250

90-110 PSI

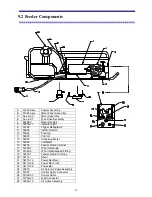

Summary of Contents for BRIDGEMASTER

Page 20: ...7 3 System Assembly drawing shows optional straighteners...

Page 30: ...17 6 2 1 Angle Spray Nozzle 3 16 4 8 mm Wire Head...

Page 31: ...18 6 3 Air Nozzle Alignment 1 8 3 2 mm Wire Head...

Page 32: ...19 6 3 2 Angle Spray Nozzle 1 8 3 2 mm Wire Head...

Page 57: ...44 9 4 1 System Wiring...