21

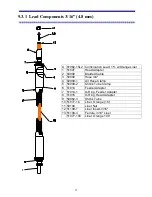

6.4.2 Combination Leads

Liners

:

The liners inside the combination leads are considered consumable parts and

require periodic replacement due to wear or accumulation of dust or grit. The wear life

can be extended by using methods to minimize the amount of dirt that gets into the

system.

Cover the wire during idle periods, especially if the equipment is going to be in

the area during surface preparation.

A wiper may be used on the wire prior to it going into the liners.

Clean liners by spraying a solvent into the liner then blowing the material through

the liner with a blow gun.

The liner replacement technique is important to insure that air flows correctly through the

leads and into the spray head, refer to Section 7 for liner replacement technique.

O-Rings

:

The o-rings at each end of the leads should be inspected and replaced if

damaged. If there is damage and part of the o-ring is missing, inspect the leads to ensure

the missing piece is not causing blockage. Lubricate the o-rings and socket, with a light

grease, prior to insertion. The grease is necessary for a good air seal at both the feeder

end and at the head.

6.4.3 Feeder Unit

The feeder unit, being low maintenance, mostly requires cleaning and periodic

inspections. Keeping the feed rolls and gearing clean of dust and grit will extend life and

provide better service. A daily cleaning with an air blow gun should be sufficient. During

this cleaning, watch for any oil leaks from the motor. The motor will not require any oil

fills unless it has leaked. Examine the feed gears to assure they align correctly and mesh

over their full width. The feed gears roll on a shaft that is not lubricated; after extended

use, the gears can wear to the point of not aligning correctly and causing feeding

problems. At this point they will require rebuilding.

6.4.4 Control Cables

The control cables require routine inspection for separation at the connectors and for cuts

or breaks in the wire coverings. If any condition of abnormality is notice it must be

remedied immediately. CAUTION: when tightening cables, turn the connectors NOT

the entire cable or the wires may disconnect and cause shorts.

Summary of Contents for BRIDGEMASTER

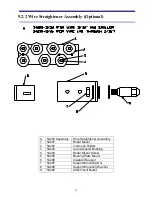

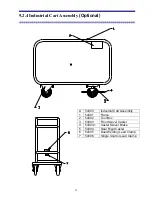

Page 20: ...7 3 System Assembly drawing shows optional straighteners...

Page 30: ...17 6 2 1 Angle Spray Nozzle 3 16 4 8 mm Wire Head...

Page 31: ...18 6 3 Air Nozzle Alignment 1 8 3 2 mm Wire Head...

Page 32: ...19 6 3 2 Angle Spray Nozzle 1 8 3 2 mm Wire Head...

Page 57: ...44 9 4 1 System Wiring...