Removal and Installation Procedures

TDS 410, TDS 420 & TDS 460 Service Manual

6Ć11

H

Disassembly for Cleaning on page 6-35 is a procedure, based on the

module removal procedures just described, that removes all modules for

cleaning. Instructions for cleaning are found in

Inspection and Cleaning,

which begins this section

. The Disassembly for Cleaning procedure does

not use the access procedure.

NOTE

Read the cleaning procedure before disassembling the oscilloscope

for cleaning.

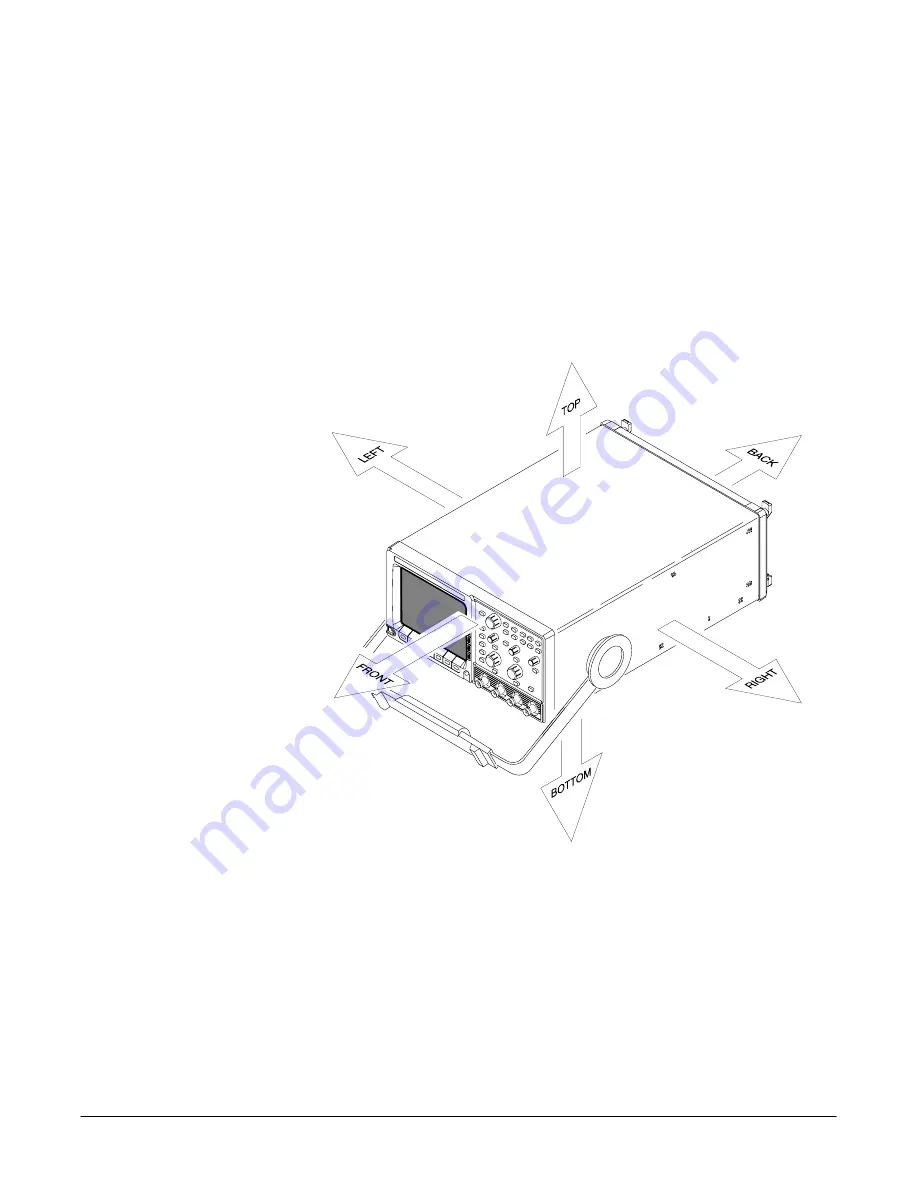

Figure 6-1: Oscilloscope Orientation

Summary of Contents for 410

Page 9: ...Contents x ...

Page 13: ...Contents xx ...

Page 19: ...Safety Summary xx ...

Page 25: ...Introduction x x ...

Page 26: ...Specifications ...

Page 47: ...Operating Information ...

Page 63: ...Operating Information Operating Information 2Ć16 ...

Page 64: ...Theory of Operation ...

Page 68: ...Circuit Description Theory of Operation 3Ć4 ...

Page 69: ...Performance Verification ...

Page 81: ...Brief Procedures Performance Verification 4Ć12 ...

Page 119: ...Performance Tests Performance Verification 4Ć50 ...

Page 120: ...Adjustment Procedures ...

Page 147: ...Maintenance ...

Page 151: ...Maintenance Information Maintenance 6Ć4 ...

Page 240: ...Options ...

Page 249: ...Electrical Parts List ...

Page 251: ...Replaceable Electrical Parts List Electrical Parts List 8Ć2 ...

Page 252: ...Diagrams ...

Page 258: ...Diagrams 9Ć6 ...

Page 259: ...Mechanical Parts List ...

Page 263: ...Mechanical Parts List 10Ć4 ...

Page 275: ...Mechanical Parts List 10Ć16 ...