TA-U1...U280

Instruction and Operating Manual

Misprints and technical changes reserved

35

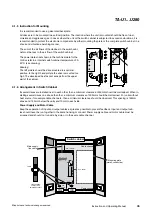

4.1.5 Instruction for Mounting

It is recommended to use a galvanized backplate.

All drives are to be mounted in a vertical position. The location where the unit is mounted should be free of dust,

moisture and aggressive gas. In cases where the unit or the switch cabinet is subjected to excessive vibrations, it is

recommended to protect the electronic components by either mounting the plate or the complete switch cabinet in a

shock and vibration absorbing manner.

The sum of the air flows of the devices in the switch cabi-

net must be less to the air flow of the switch cabinet.

The power data sheet shown in the technical data for the

U-drive refer to a internal switch-cabinet-temperature of 0 -

40°C. (see drawing)

Drawing

The left picture shows the drive mounted in a optimal

position. In the right hand picture the drive is mounted too

high. The developed heat cannot escape from the upper

part of the cabinet.

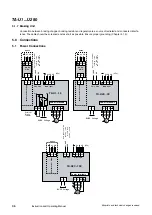

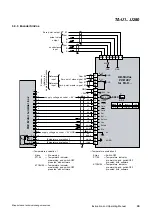

4.1.6 Arrangement in Switch Cabinet

If several drives are installed next to each other, then a minimum clearance of 50mm should be maintained. When in-

stalling several drives one above the other, a minimum clearance of 300mm should be maintained. For units without

heat source,-for example cable channels - then a minimum clearance should be observed. This spacing is 150mm

above and 150mm below the units and 10mm to each side.

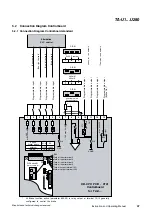

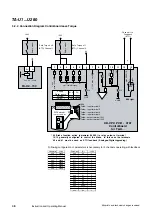

Power Supply and Motor Cable

Keep the separation of input and output cables as great as possible to prevent feedback. Input and output cab-

les should never be run together in the same trunking or conduit. Power supply cable and motor cable must be

screened and should not run side by side, or in the same cable channel.

min.

150mm

min. 150mm

4Q

SR

B

A

I-L

V

U

Bus

W

RS 422 / 485

universal drive

TA-U37 / 45

U-

DRIVE

PG 4000

PG 4001

M

min. 10mm

Cable channal

Cable channal

Switch cabinet

Main supply

line cable

Mounting plate

(metall, conductive)

Large surface

contact with

shielding conduit

cable

Sensor

cable

motor

cable