TA-U1...U280

Instruction and Operating Manual

Misprints and technical changes reserved

49

7.2 Fault Description

F0

Motor over temperature:

a) Overload motor.

b) Sensor cable defective.

c) Temperature control defective.

F1

Overcurrent switch-off:

a) Short-circuit power stage.

b) The motor has a winding short-circuit or a ground fault.

F2

Over zemperature power stage:

The heat sink temperature of the device has max. tempera-

ture exceeded ( > 80 ° C ):

a) The ambient temperature is too high ( about 40 ° C ).

b) The internal fan is faulty.

c) The permanent current of the device (I

rated

) is exceeded.

d) The device is wrongly mounted (see chapter 4.1.6 Arran-

gement in Switch Cabinet ).

F3

Buss undervoltage:

The buss voltage is too low:

a) Mains too low.

b) A phase is missing.

c) Contactor K1 is not switching or defective.

F4

Buss overvoltage:

The buss voltage is too high (>780V) :

a) The device current in 4Q operation is too high for at-

tached chopper or braking resistor.

b) The 4th quadrant is operate without chopper.

F5

Ripple current:

The ripple in the buss voltage is too high:

a) A phase is missing

b) Buss capacitor is defective.

F6

Position sensor U, V and W:

The feedback of the motor about the rotor position is faulty:

a) Cables or plugs defective.

b) Position sensor, sensorboard or encoder assembly is

defective. (refer to Operating & Maintenance Manual of

the motor ).

F7

Speedsensor:

The feedback from the speedsensor is faulty:

a) A or B is not conected

b) A with B is exchanged

F8

Elektronic:

F9

Short-circuit IGBT / motor ground fault:

a) Short-circuit at output U, V, W.

b) Motor power cable defective.

c) Power stage (IGBT) defective.

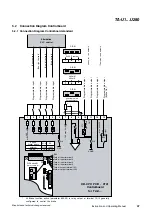

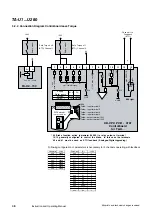

E1

External error:

An external error can be release by a digital input. The input

can supervise e.g. overcurrent release from a independent

blower of the motor