4.4

Installation location for agriculture

In order to avoid damage caused by ammoniac vapours, the controller shall not be installed in the

stable, but rather in an outhouse wherever possible.

4.5

Temperature in

fl

uences during commissioning

Avoid condensation in the controller and functional faults attributable to condensation by storing the

controller at room temperature!

5

Electrical installation

5.1

Safety precautions

Danger due to electric current

•

Work on electric components may only be carried out by trained electricians or by persons

instructed in electricity under the supervision of an electrician in accordance with electrical

engineering regulations.

•

The 5 electrical safety rules must be observed!

•

It is forbidden to carry out work on electrically live parts. Even after disconnection, the dc-link is still

live. Always wait at least 3 minutes.

•

Other measures may be necessary to achieve safe electrical isolation.

•

A second person must always be present when working on energized parts or lines who discon-

nects in case of emergency.

•

Inspect electrical equipment periodically: retighten loose connections

–

immediately replace dam-

aged lines and cables.

•

Always keep switch cabinets and all electrical supply facilities locked. Access is only allowed for

authorized persons using a key or special tool.

•

Operating the device with the housing cover removed is prohibited because energized, exposed

parts are present inside the device. Disregarding this regulation can lead to severe personal injury.

•

For metal cable inlets the necessary protective earth connection to the bottom of the housing is

made by screws. The device may only be started up when these screws are

fi

tted properly.

•

The device owner is responsible for the EMC of the entire plant according to the locally applicable

standards.

•

Never clean electrical equipment with water or similar liquids.

Information

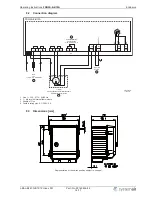

The respective connections are represented in the enclosure of this manual (

Connection diagram)!

5.2

EMC-compatible installation

5.2.1

Motor cable

The applicable standard for interference emissions is EN 61000-6-3. Compliance with this standard is

achieved through the use of an unscreened motor feed cable.

5.2.2

Control cables

Pay attention to suf

fi

cient distance from powerlines and motor wires to prevent interferences. The

control cable may not be longer than 30 m. Screened control cables must be used when the cable

length is longer than 20 m. When using a shielded cable connect the shielding to one side only, i.e.

only to the control unit with the protective ground (keep cable short and with as little inductance as

possible!).

5.3

Mains connection

5.3.1

Line voltage

Power from the mains is connected to terminals: PE, L1 and N. Here, it must be strictly observed that

the mains voltage lies within the allowable tolerance speci

fi

cations (

Technical data and nameplate

af

fi

xed to the side).

A connection between two phase conductors is possible for 3 ~ 230 V supply networks.

Operating Instructions

FRQ5S-E-6/10A

Electrical installation

L-BAL-E247-GB 1512 Index 001

Part.-No. 00163444-42

9/17