3

Product overview

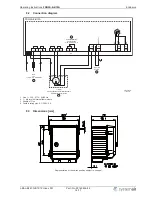

3.1

Operational area

Frequency inverter designed for a stepless control of fans without additional (electromagnetic) motor

noise.

By using the integrated all-pole effective Sine

fi

lter (phase to phase and phase to ground), an absolute

parallel control of fans without risk of damage for motors is possible. Screened motor cables are not

required!

Only suitable for drives with low set-off torque (e.g.: fans or pumps).

3.2

Functional description

Frequency inverters of these series generate their 3 ~ output with variable voltage and frequency from

the 1 ~ AC mains network on the input.

The devices are constructed in accordance with the general requirement in EN 61800-2 for adjustable

speed electrical power systems and is intended for one-quadrantdrives.

The PFC (Power Factor Controller) makes the output voltage mostly independent of the mains

voltage.

The fan speed is preset with the 5-step switch.

Step

Output frequency *

Direct switching from step

“

0

”

to step

“

5

”

or from step

“

5

”

to

step

“

0

”

is not possible!

0

1

2

3

4

5

0 Hz

10 Hz

20 Hz

30 Hz

40 Hz

50 Hz

23.05.2013

v_5_step_icontr_basic_sa.vsd

*

The output frequency can be adapted by an internal potentiometer if necessary (

inverter output: U/f-characteristic

curve).

Danger due to electric current

In

step

“

0

”

the frequency inverter is not switched off electrically

but only no speed preset signal

applied (= 0 V).

3.3

Maintenance

The device must be checked for soiling and, if necessary, cleaned in periodic intervals.

3.4

Transport

•

The device is packed ex factory to suit the transport method previously agreed.

•

Always use the original packaging materials when transporting the device.

•

Avoid shocks and impacts to the device during the transport.

•

During manual handling the human lifting and carrying restrictions must be observed and adhered

to.

3.5

Storage

•

The device must be stored in its original packaging in a dry and weather-proof room.

•

Avoid exposure to extreme heat and cold.

•

Avoid prolonged storage; we recommend a maximum of one year (consult the manufacturer before

starting if stored for longer).

Operating Instructions

FRQ5S-E-6/10A

Product overview

L-BAL-E247-GB 1512 Index 001

Part.-No. 00163444-42

7/17