3.6

Disposal / recycling

Disposal must be carried out professionally and environmentally friendly in accordance with the legal

stipulations.

4

Mounting

4.1

General notes

Attention!

The following points must be complied with during the mechanical installation to avoid causing a defect

in the device due to assembly errors or environmental in

fl

uences:

•

Before installation remove the device from the packing and check for any possible shipping

damage!

•

Assemble the device on a clean and stable base. Do not distort during assembly! Use the

appropriate mounting devices for proper installation of the unit!

•

A mounting on vibrating base is not permissible, if no data to the vibration strength is made (

Technical data)!

•

When mounted onto lightweight walls, there must be no impermissibly high vibrations or shock

loads. Any banging shut of doors that are integrated into these lightweight walls, can result in

extremely high shock loads. Therefore, we advise you to decouple the devices from the wall.

•

Do not allow drilling chips, screws and other foreign bodies to reach the device interior!

•

Maintain the stated minimum clearances to ensure unobstructed cooling- air feed as well as

unobstructed outgoing air discharge (

minimum space requirement)!

•

The device should be installed in a location where it will not be disturbed, but at the same time can

be easily accessed!

•

Depending on the housing model cut off necessary cable inlets respectively to the cable diameter.

Or alternative use cable inlet for cable glands. Metal sheet housings are supplied with stoppers.

Any cable ducts openings not used must be sealed!

•

Care must be taken to avoid direct radiation from the sun!

•

The device is designed for vertical installation (cable inlet down). A horizontal or reclined installation

is only permissible after technical release of the manufacturer!

•

Be sure to observe proper heat dissipation (

Technical data, heat dissipation).

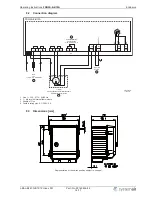

4.2

Minimum space requirement

In order to ensure suf

fi

cient ventilation of the device, clearance on all sides of at least 50 mm has to

be maintained to the housing walls, switch cabinet doors, wiring ducts, etc. The same clearance

applies to the installation of several devices next to each other.

When installing several devices on top of each other, the danger of reciprocal heating exists. This

layout is only then permissible when the air suctioned from the upper unit does not become warmer

than the permissible ambient temperature (

Technical data). I.e., a correspondingly larger clearance

or thermal shielding is required.

4.3

Outdoor installation

Outdoor installation is possible up to -20

°

C when the controller supply is not switched off. Installation

must be protected from the effects of weather as much as possible, including protection from direct

sunlight!

Operating Instructions

FRQ5S-E-6/10A

Mounting

L-BAL-E247-GB 1512 Index 001

Part.-No. 00163444-42

8/17