7

Diagnostics / Faults

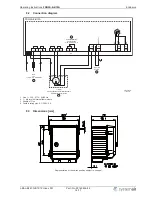

Operating conditions are indicated by the status LED with

fl

ashing code.

04.01.2012

v_flash_explain1_8.VSD

3 x

2 x

ON

OFF

5 x

1 x

7 x

8 x

Code

Relay

K2

Explanation

Reaction of Controller

Adjustment

OFF

de-energized

terminals 21 - 22 bridged

No line voltage

In the event of a mains interruption the

unit switches

“

OFF

”

and automatically

“

ON

”

when the voltage has been re-

stored.

Check line voltage and pre-fusing.

ON

Energized at modulation

above 5 Hz (terminals 21 -

24 bridged).

De-energized at modula-

tion below 3 Hz (21 - 22

bridged).

Normal operation without fault

1

de-energized, 21 - 22

bridged

No enable = OFF

Terminals

“

D1

”

-

“

D1

”

(Digital In 1) not

bridged.

Switch off by external contact (

enable,

device ON / OFF).

2

de-energized

terminals 21 - 22 bridged

Motor fault

Tripping of connected thermostat or

break between terminals

“

TB

”

.

The unit cuts out and does not switch on

again.

Check motor and connection then reset

(

Motor protection).

3

Energized at modulation

above 5 Hz (terminals 21 -

24 bridged).

De-energized at modula-

tion below 3 Hz (21 - 22

bridged).

Temperature management active

The device has an active temperature

management to protect it from damage

due to too high inside temperatures. In

case of a temperature rise above the

fi

xed limits, the modulation is reduced lin-

early. To prevent the complete system

being switched off externally (in this oper-

ation permissible for the controller) in

case of reduced operation due to too high

an internal temperature, no fault message

is sent via the relay.

With a drop in temperature the modula-

tion rises again llinear.

Check cooling of the controller

5

de-energized

terminals 21 - 22 bridged

Overcurrent

The controller was switched off by the

current limitation.

Delay: 1.25 sec by continous overcurren-

t.Immediately switch of after 16th short (<

1.25s) overcurrent.

If for 60seconds no short fault the fault

counter goes back to 0 .Switch back time:

60 sec.

Controller turns the motor off. There is a

renewed attempt to start after about one

minute.

Check motor

Operating Instructions

FRQ5S-E-6/10A

Diagnostics / Faults

L-BAL-E247-GB 1512 Index 001

Part.-No. 00163444-42

13/17