FAAST 7100X

INSTALLATION AND MAINTENANCE INSTRUCTIONS

© Pertronic Industries Ltd

9

FAAST XS (7100X) Installation Guide Iss 1.0, 201606

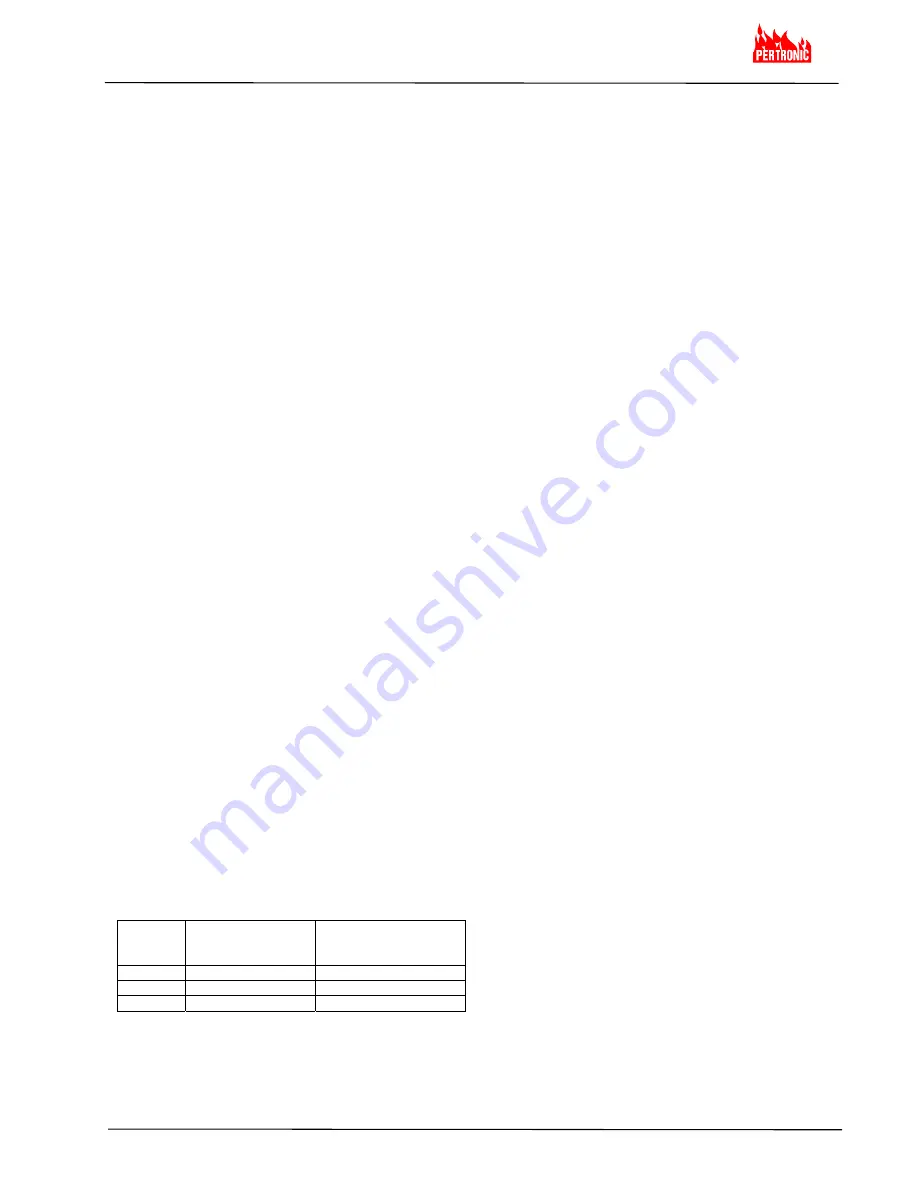

Alarm

Level

Default Threshold

(%Obs/m)

Programmable Range

(%Obs/m)

Alert

0.0396

0.00095 – 20.0

Fire 1

0.825

0.00095 – 20.0

Fire 2

1.65

0.00095 – 20.0

Table 5 : Programmable Alarm Levels

Modes of Operation:

Initialisation:

When the FAAST XS system is initially powered up it is

not configured, a

Fault indication is set with the General

Fault LED and the LCD Home screen

displays a

Configuration Fault. This indicates that the device has

not had

its initial configuration loaded and remains in

this fault state until a valid

configuration is sent to the

device. Upon configuration, the device

performs an

initialisation - this resets the Air-Flow and Filter clogged

baselines. It is important that the system has been

connected correctly to the pipe network and the Filter is

installed properly when

the device is initialised as these

baselines are used to indicate when a Fault

should

occur. During the initialisation period the device

operates as normal, though.accurate Flow and Filter

statuses will not display until the baseline is set.

Establishing the baseline takes approximately five

minutes.

Configuration Overview:

FAAST XS is configured using PipeIQ. Data is sent via

an in-built Ethernet connection or through the USB

interface located inside the wiring cabinet. The device

receives and validates the configuration before the

configuration becomes active. After the data is validated

the device performs an initialisation with the new

configuration. If there is a problem with the configuration

data the device indicates a Configuration Fault on the

User Interface and sets the Fault relay. The device will

require a new configuration before operating correctly

Fan Speed Configuration:

The device is capable of running at 3 different fan

speeds. To minimize power use, the lowest fan speed

that meets the requirements should be selected. The

fan-speed directly affects the performance of the device.

Likewise, pipe network calculations performed in PipeIQ

are based on the fan setting. If the fan setting is

changed on the device at a later date the pipe system

must be re-verified

Alarm and Relay Configuration:

Alarm thresholds are set to default levels when shipped,

but are configurable. Each Alarm level has its own set of

Form C relay contacts. As the particulate level crosses

the threshold for the alarm level the corresponding

indicator illuminates and the relay activates. The Alarm

thresholds and their associated relay outputs are

configurable for latching or non-latching operation. For

each Alarm level, there is a configurable delay from 0 to

60 seconds.

Configurable thresholds for each alarm level are:

Audible Indicator Configuration:

The FAAST XS has an integrated audible indicator

which provides the option to include a supplementary

audible indication for Alarms and Faults - the settings

are configurable using PipeIQ software.

The sounder is capable of generating a pulsed or

continuous tone. The Alarm and Fault can be selected

to do either tone.

Note: these tones are not NZS4512 compliant, so an

Alarm tone should be used with caution

Power Glitch During Configuration:

During an upload of configuration data, the device

retains the last known

valid configuration in memory

until a complete validation is done on the new

configuration data - this prevents device corruption in

the event of a power

loss or network failure. After

power has been restored the device initialises with the

last known good configuration. The device also

indicates a

Configuration Fault on the user interface

and sets the Fault Relay. This occurs just once - after

the next Reset or Power-on-Reset the device continues

to

use the last known good configuration

Normal:

During Normal operating mode the FAAST XS displays

the Airflow and current

P

articulate Levels on the user

display. The Time, Date, Address and current

Obscuration is shown on the LCD. The Particulate

Level is compared to the

Threshold

Levels programmed

into the device and activates the appropriate Alarm as

the particulate exceeds that threshold. If a fault occurs

it activates the Fault LED, displays the type on the LCD

and sets the corresponding relay

Test:

Test mode is initiated through the PipeIQ Live View tab

or through the LCD interface. Test mode simulates a

Fire condition by activating all ten segments

in the

Particulate Level display and each segment in the

Alarm display. Each

corresponding Alarm relay

activates after any programmed delay associated with

that relay. To remove the device from Test, a RESET

must be performed

Sounder Test:

The Sounder Test function can be accessed from the

LCD user interface. When

initiated, the device activates

the selected sounder tones for Fault and

Alarm

conditions. The sounder may be configured to give

continuous or pulsed

tones for Alarm and Fault

conditions. Tones may be selected using PipeIQ

Reset:

Reset mode is initiated through the PipeIQ mimic view

or through the LCD interface. When RESET is

activated all relays are reset. It then enters

Normal

mode operation. If any Fault or Alarm states remain,

the device reactivates the state automatically