FAAST 7100X

INSTALLATION AND MAINTENANCE INSTRUCTIONS

© Pertronic Industries Ltd

11

FAAST XS (7100X) Installation Guide Iss 1.0, 201606

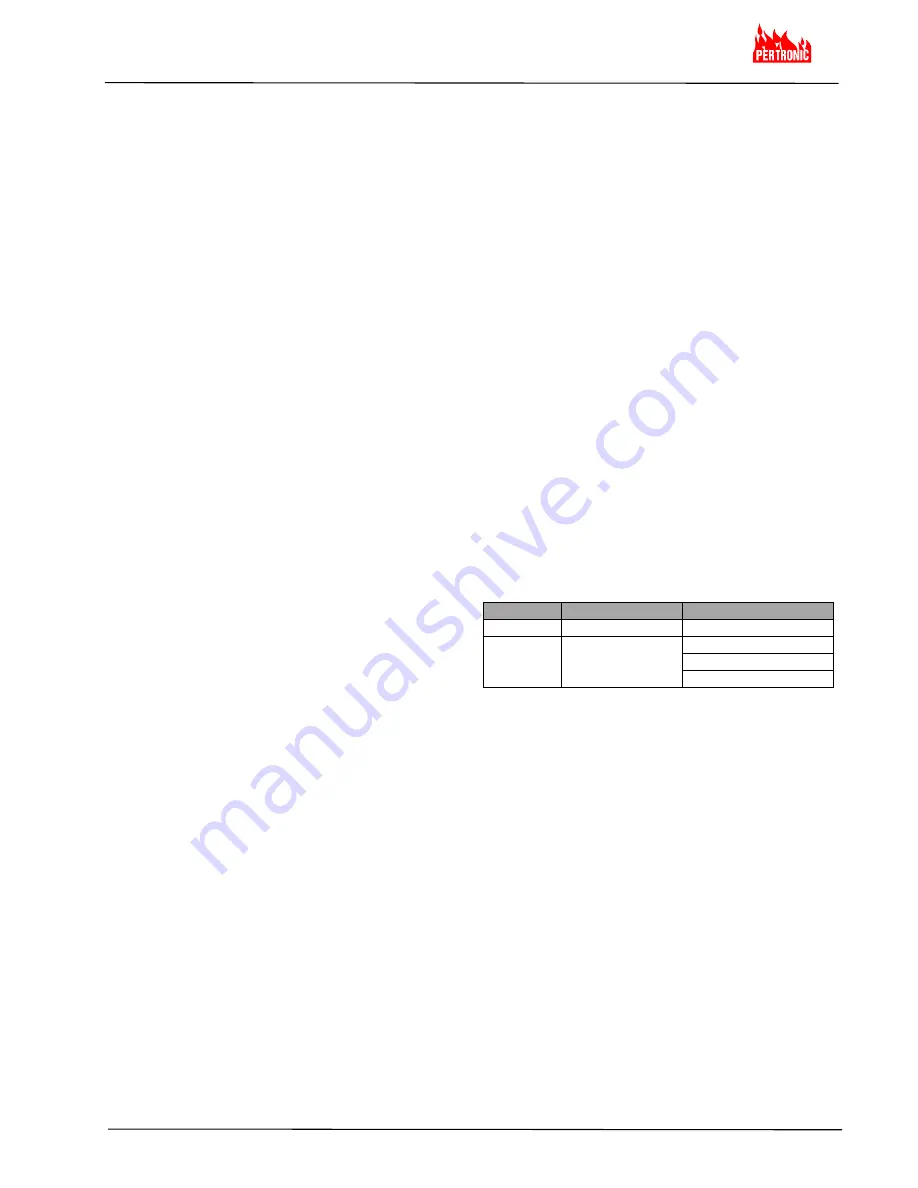

Table 7 : Canned Smoke Testing

Maintenance

The only periodic maintenance required is to replace

the filter assembly when the Filter light is illuminated.

Perform the following procedure to replace the filter

assembly.

1. Remove power from the system.

2. Open the door on the right side of the device that

covers the LED system indicators.

3. Remove the plastic name card over the LEDs.

4. Remove the two screws holding the filter assembly

into the device.

5. Remove the filter assembly and replace it with a

new assembly.

6. Torque the two Philips head screws to 0.7N-M or ¼

turn past “lightly snug.”

PLEASE DO NOT OVERTIGHTEN.

7. Replace the plastic name card over the LEDs.

8. Close the door and return power to the system.

Other system checks may need to be performed in

accordance with local or national codes and

regulations.

UL Listing

Company

Aerosol

UL Home

Safeguard

25S

UL SDI

LLC

CHEK02, CHEK06

SOLOA3

SMOKE SABRE-01

Logs:

Event Log:

The FAAST XS system has internal memory that can

be configured to log detector events. Up to 18,000

events can be stored. Events that are tracked include

Alarms, Faults, and User actions. Event tracking may

be

accessed via the network through the PipeIQ

software or the web server interface. Configuration and

management of the log are done using PipeIQ.

Data Trend Log:

The FAAST system can track data from its sensors in

the Trend Log. Using PipeIQ the frequency which the

data is recorded can be selected to

allow higher

resolution. The rate is limited to a range of 1 to 60

minute or 1 to

24 hour periods. Depending on the rate

chosen, data can be collected for 72

hours up to 11.8

years

Message Log:

The Message Log allows the user to enter generic text

messages into the device’s storage memory. Messages

may be retrieved for viewing later. The messages may

be used to track service history, configuration changes,

etc. A maximum of 300 messages may be stored

External Monitor / Reset:

The FAAST 7100X has an External Monitor that can

detect an open or short when the supplied 47K

Ω

end of

line resistor is used. When the device senses an open-

circuit it sets the External Monitor Fault indicator and

sets the Fault relay. When a short-circuit is detected the

device performs a Reset - this provides the ability to

reset Alarm latches remotely

Connections

Ethernet Connection:

The

FAAST XS system is a network capable device that

is compatible with standard Ethernet networking

equipment. Connectivity is provided by an on-board

RJ45 connector located inside the wiring cabinet. Once

initial setup is complete, the Ethernet connection

provides optional remote access, monitoring and

notification through the unit’s Web server and SMTP

client

USB Connection:

A USB port located in the wiring cabinet allows

configuration and monitoring through PipeIQ or the

retrieval of data from the device

Pipe Network:

The unit can monitor up to 600m

2

with a properly

designed pipe network. The pipe network must be

configured using the PipeIQ software. The pipe network

accommodates a maximum single pipe length of 80m.

The device is capable of both metric 25mm and IPS

1.05in. pipe outside diameters without the use of an

adaptor. The internal pipe diameter can range from 15-

21mm. The pipe must be installed such that only the

top or bottom air inlet port is used - mixed sampling

from the top and bottom ports is not recommended.

Pipe networks may be constructed of various materials

such as uPVC, cPVC, PVC, ABS, copper or stainless

steel pipe. Travel time from the furthest hole depends

on the application of the device, but is limited to a

maximum of

120 seconds by the PipeIQ software.

NZS4512 limits the Maximum Transport Time to 90

seconds

Web Server

The FAAST system contains an integrated Web server

which is used to observe detector configuration and

may be used to remotely monitor the unit.

The Web server features include:

• Intuitive interface for remote monitoring of faults,

relays, particulate level, air flow, and power supply

• Facility location and contact information

• Configuration settings display

• Multi-Lingual support

• Event log viewer

Email Notification

The FAAST system has the ability to send e-mail

notifications to an individual or organization. Up to 6

different email addresses may be stored for notification.

Each email address can be configured to be notified of

a specific Alarm level, Fault level or Isolate condition

through the PipeIQ software. E-mails from the device

indicate a device’s ID, location and Alarm or Fault type.

A comprehensive networking guide may be downloaded

at: www.systemsensor.com/faast.

Smoke Tests

All FAAST systems must be tested after installation and

periodically thereafter.

Test methods must satisfy the (AHJ) authority having

jurisdiction. Systems offer maximum performance when

tested and maintained in compliance with NFPA 72.

Pertronic Industries recommends the use of Smoke

Pens (PN: SMOKEPEN) however tested and approved

aerosol smoke products are listed in Table 7.