172

4.5.7.2 Lubricate swing mechanism

Stop the machine at level ground, lower the

bucket to ground.

Stop auto-idle switch, run the engine unloaded

at low speed for 5 minutes.

【Important】

Stopping the engine improperly may

damage turbocharger.

Set start key to OFF position, stop the engine,

remove the key from starting lock, set safety

lock lever to LOCK position.

Loosen 2 bolts of grease fill port cover located

on front part of turret. Then remove grease fill

port cover (1).

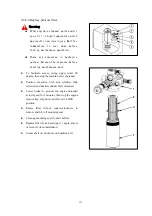

Check that grease height in the position where

pinion passes by should be at least 14mm

(0.6in), and free of pollution; add 0.5kg

lubricate grease to reach standard height if

necessary.

Check the color of the grease, in case of white,

change it.

Drain port locates around central swing joint

under lower carriage frame.

4.5.7.3 Replace engine oil, oil filter.

For detail, refer to chapter 4.5.2.1.

4.5.7.4 Replace fuel filter

For detail, refer to chapter 4.5.2.3.

4.5.7.5 Replace fuel preliminary filter

For detail, refer to chapter 4.5.2.4.

4.5.7.6 Clean up cooler

For detail, please refer to chapter 4.5.3.2.

Summary of Contents for SWE150F

Page 19: ...12 18 No unauthorized access label Warning Stay clear of operation area of working device...

Page 22: ...15 23 Gravity label 24 Hydraulic oil label 25 Greasing...

Page 151: ...144 4 4 9 Hose...

Page 193: ...186 5 Technical specification...

Page 197: ...190 5 1 4 Circuit diagram...

Page 199: ...192 5 1 6 Hydraulic diagram...

Page 204: ...197 5 2 4 SWE210F Circuit diagram...

Page 206: ...199 5 2 6 Hydraulic diagram...